current position:Information and data>Power supply for arc spray equipment

Although the arc spraying can use the general arc welding rectifier power supply, it is not the most suitable due to its great limitations in characteristics, and has been replaced by a special power supply that is more suitable for spraying in terms of external characteristics and dynamic characteristics.

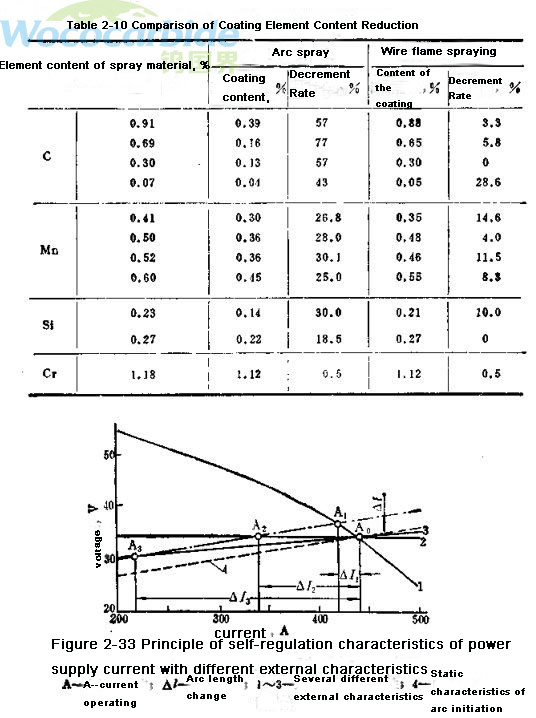

Based on the particularity of the wire melting-atomization process in the arc spraying process, when the arc length fluctuates at a high rate and the wire feeding rate changes, in order to maintain the arc stability, it is required that the arc tortoise current can follow the arc length. Small changes increase or decrease rapidly, that is, when the arc length becomes smaller, the current can quickly rise to a sufficient level to accelerate the melting of the wire and restore the arc length. When the arc length becomes larger, the current can quickly decrease, reducing the melting of the metal. to restore the arc length. According to such requirements, the external characteristics of the power supply should be flat characteristics or slightly rising external characteristics, and the dynamic characteristics should have a sufficiently large current rising rate. As shown in Figure 2-33, the flat or slightly rising outer characteristic has much stronger current self-regulation performance than the steeply falling outer characteristic. The current rise rate generally reaches 104-105A/s. Due to the high rate of current rise, it is generally difficult for power supplies with magnetic saturable reactors to achieve such a high rate of current rise.

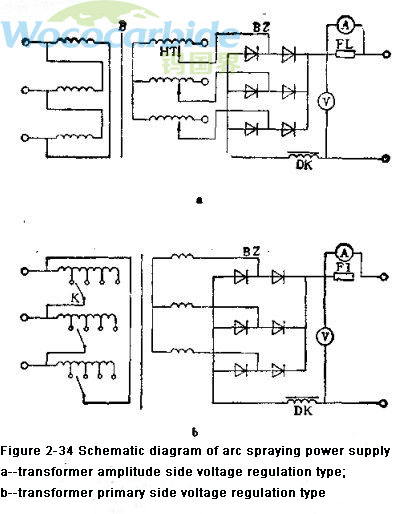

In order to adapt to the choice of spraying different metal materials and process, the output voltage of the power supply should be adjusted within a certain range, therefore, there should be an output voltage adjustment device in the design of the power supply. There are generally two ways to adjust the output voltage, one is to change the number of coil turns on the secondary side of the transformer, and the other is to change the number of coil turns on the primary side of the transformer. Figure 2-34 is the circuit schematic diagram of the spraying power supply.

In order to adapt to the choice of spraying different metal materials and process, the output voltage of the power supply should be adjusted within a certain range, therefore, there should be an output voltage adjustment device in the design of the power supply. There are generally two ways to adjust the output voltage, one is to change the number of coil turns on the secondary side of the transformer, and the other is to change the number of coil turns on the primary side of the transformer. Figure 2-34 is the circuit schematic diagram of the spraying power supply.

Hot information