current position:Information and data>Melting-Atomization Process in Arc Spraying Process

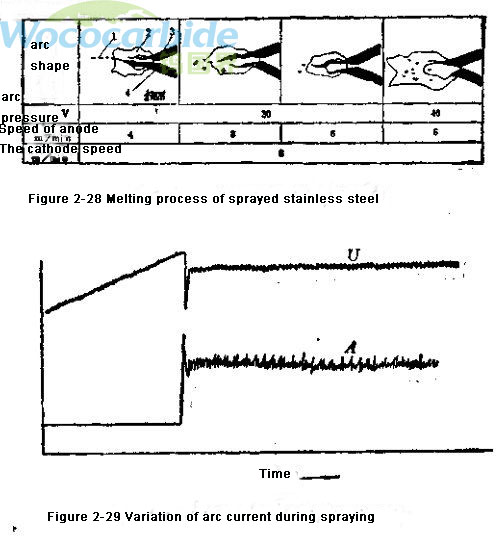

Under normal circumstances, the two metal wires are only in an instantaneous short-circuit state at the beginning of spraying. During the spraying process, under the action of the arc, the ends of the two electrode wires frequently produce metal melting-melting metal detachment-droplets are atomized into particles. Process. The melting rate of anode and cathode is different in each process, but the overall melting rate is the same (as shown in Figure 2-28). During the melting process of the end of the wire, the distance between the electrodes changes frequently. When the power supply voltage remains constant, due to the self-regulating characteristics of the current, the arc current fluctuates frequently and automatically maintains the melting speed of the wire (as shown in Figure 2- 29), the arc current also increases with the wire feed speed.

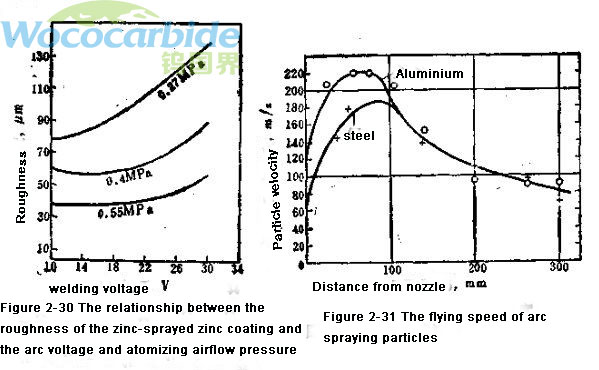

One of the biggest concerns with arc spraying is coating roughness, which depends on the size of the particles after atomization. There are many factors that affect the thickness of atomized particles, mainly including: as the pressure of the atomizing airflow increases, the particles become thinner (as shown in Figure 2-30), and the higher the arc voltage, the thicker the micro-pull (as shown in Figure 2-30). shown), the angle between the two metal wires is small, and the particles are finer, and the atomized particles of low melting point metals are thinner than those of high melting point metals. In addition to the above factors, the structure of the nozzle also affects the thickness of the atomized particles. The use of closed nozzles can produce finer atomized particles than open nozzles.

One of the biggest concerns with arc spraying is coating roughness, which depends on the size of the particles after atomization. There are many factors that affect the thickness of atomized particles, mainly including: as the pressure of the atomizing airflow increases, the particles become thinner (as shown in Figure 2-30), and the higher the arc voltage, the thicker the micro-pull (as shown in Figure 2-30). shown), the angle between the two metal wires is small, and the particles are finer, and the atomized particles of low melting point metals are thinner than those of high melting point metals. In addition to the above factors, the structure of the nozzle also affects the thickness of the atomized particles. The use of closed nozzles can produce finer atomized particles than open nozzles.

The atomized particles fly under the impetus of the compressed air flow, and the flight speed of the particles is initially accelerated, and then decelerated as the spray distance increases (as shown in Figure 2-31).

Hot information