current position:Information and data>Introduction of powder flame spray welding equipment

The composition of powder flame spray welding equipment is the same as that of powder flame spraying, except that a remelting gun should be added to the spray gun, and necessary heating and slow cooling devices should be added to the auxiliary equipment, so that the temperature change of the workpiece can be effectively controlled during the remelting process. .

For spray welding of small workpieces, especially one-step spray welding, only oxygen, acetylene supply device and spray gun are needed, so the equipment is simple in composition and convenient in movement.

spray gun

The spray gun is the main tool for oxyacetylene flame spray welding. The requirements for the spray gun are: (1) The flame burns stably, is not easy to temper, and the flame power can be adjusted in a wide range; (2) The powder feeding switch is flexible, sensitive and reliable; The powder is smooth, the powder is concentrated, and it is not easy to block; (4) It can adapt to spray welding in various positions.

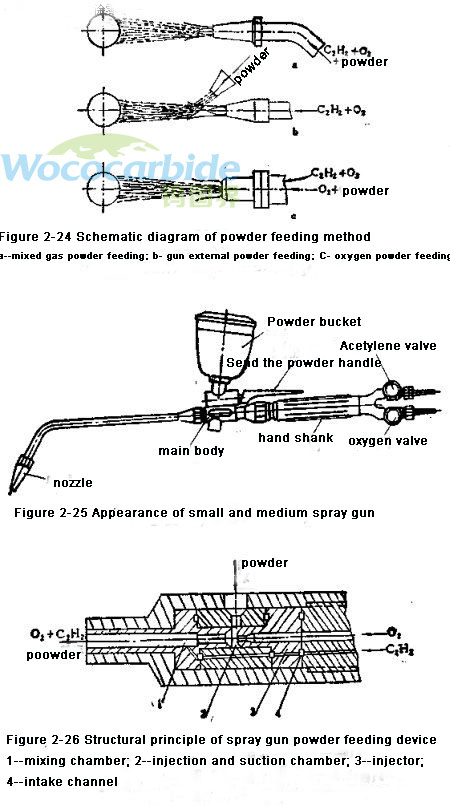

The spray gun is different from the general gas welding gun. The main difference is that the powder delivery mechanism is attached to the spray gun. Powder feeding methods can be divided into three categories (as shown in the figure): (1) powder feeding with oxygen-acetylene mixture in the gun, (2) powder feeding outside the gun, (3) powder feeding with oxygen inside the gun. When the mixed gas feeds the powder, the powder will be heated greatly through the flame core, which is beneficial to the powder melting, but the powder flow will affect the flame when feeding the powder, so it must be carefully adjusted. At present, small and medium-sized spray welding guns mostly use this powder feeding method. Oxygen is used to feed the powder, and the mixture gas and powder feeding gas used for combustion have independent channels, and the adjustment parameters do not affect each other, but the powder does not pass through the flame core, and the heating temperature is slightly lower, so use a spray gun. Powder feeding outside the gun is mainly used for high-power two-step spray welding.

According to the mixing method of acetylene and oxygen, spray guns are divided into two types: injection type and isobaric type. At present, injection type is mostly used.

At present, the most commonly used is the small and medium-sized spray welding torch, which can be used for both one-step spray welding and two-step spray welding. Its shape and structure are shown in Figure 2-25. This type of spray gun is of the injection-suction type, which uses a mixture of gas to feed the powder. The injection and suction structure of oxygen suction acetylene and the adjustment mechanism of oxygen and acetylene flow are the same as the principle of ordinary welding torch, and the shape is also similar, which is centrally installed on the handle. Different from ordinary welding torches, a powder conveying device is added, which consists of powder tank (powder hopper), powder feeding valve and injection and suction chamber. The structure principle is shown in Figure 2-26.

Hot information