current position:Information and data>Aluminum Clad Nickel | Aluminum Nickel Powder

Aluminum clad nickel is a composite powder formed by cladding aluminum on the surface of the nickel core.

Powder composition: Ni: 95, Aluminum: 5. The particle size is generally -90 +45μm.

Production method: The production process of aluminum-coated nickel powder mainly adopts the bonding method to bond the aluminum powder and the nickel core powder through a binder (phenolic resin + diluent) to form a composite powder.

The production process is: aluminum powder raw material - mixing - pulping - adding nickel powder - mixing - drying - crushing - screening.

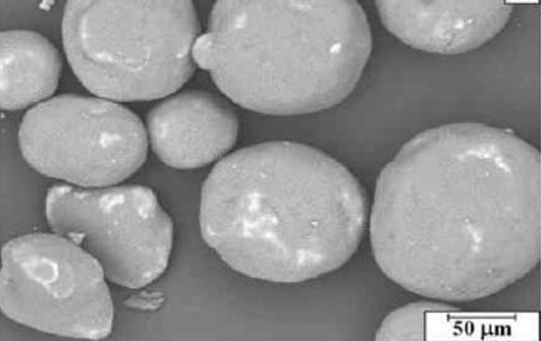

The morphology of the aluminum clad nickel powder is as follows.

Aluminum-nickel powder is a powder obtained by gas atomization.

Powder composition: Ni: 95, Aluminum: 5. The particle size is generally -45 +11 µm

Production method: 95% nickel and 5% aluminum are heated and melted in an induction heater, the molten metal liquid flows into the nozzle, and high-pressure gas is introduced into the nozzle, and the metal liquid is atomized (gas or water atomization can be used) , the atomized metal droplets are cooled and solidified during the falling process to form solid powder.

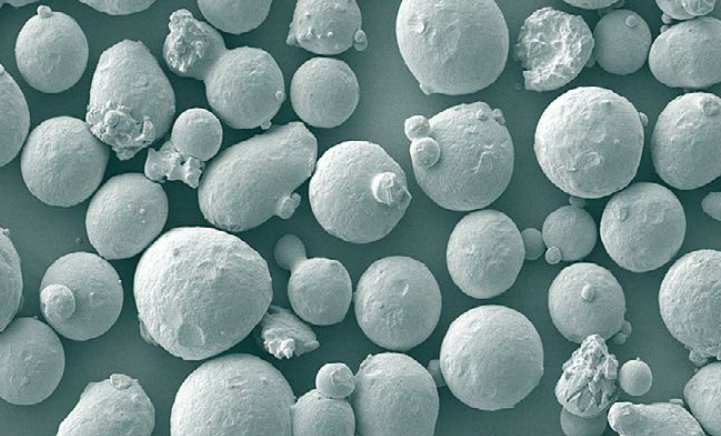

The topography of aluminum nickel powder (gas atomization) is as follows.

The spraying process of aluminum clad nickel is similar to that of nickel clad aluminum, see nickel clad aluminum powder. There is also an exothermic reaction in the spraying process. Due to the different forms of coating and the composition ratio of nickel and aluminum, the composition and phase structure of the coating are different. For specific differences, see the difference between nickel-coated aluminum powder and aluminum-coated nickel powder.

The spraying process of aluminum clad nickel is similar to that of nickel clad aluminum, see nickel clad aluminum powder. There is also an exothermic reaction in the spraying process. Due to the different forms of coating and the composition ratio of nickel and aluminum, the composition and phase structure of the coating are different. For specific differences, see the difference between nickel-coated aluminum powder and aluminum-coated nickel powder.

The aluminum-nickel powder is atomized into powder. The aluminum and nickel in the powder are not separated from each other to form α-Ni. For details, please refer to the article Will you choose thermal spraying material? No heat is released during spraying.

The spraying methods that can be used for aluminum-coated nickel powder: flame spraying, plasma spraying. The most suitable spraying method for aluminum-nickel powder (gas atomization): supersonic flame spraying, explosive spraying.

Main use of powder: same as nickel clad aluminum.

Coating properties: The coating properties of aluminum-clad nickel by flame spraying and plasma spraying are similar to those of nickel-clad aluminum. The bonding strength of the coating using supersonic flame spraying and explosive spraying gas atomized aluminum-nickel powder can exceed 80MPa, and the porosity is less than 1%.

Hot information