current position:Information and data>Nickel (Ni) Powder

The main components of nickel powder are: nickel > 99.3%, the commonly used powder particle size: - 104 + 48um, - 74 + 48um, the powder morphology is different due to the different milling methods.

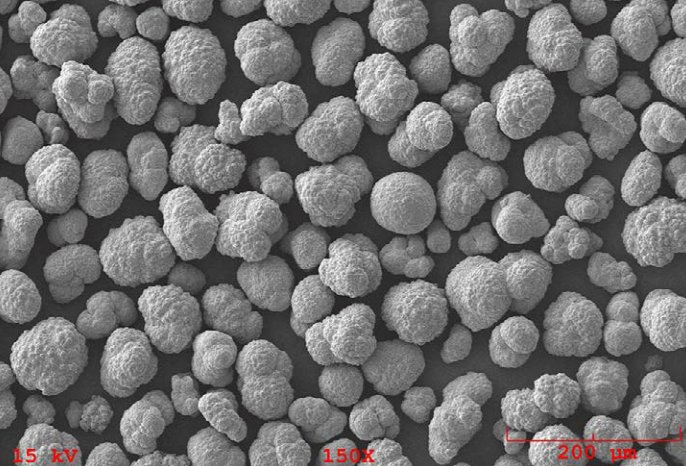

Production method: usually produced by the hydrogen reduction method of liquid-phase precipitation solution, and the morphology of the powder produced by liquid-phase precipitation method is shown in Figure 1.

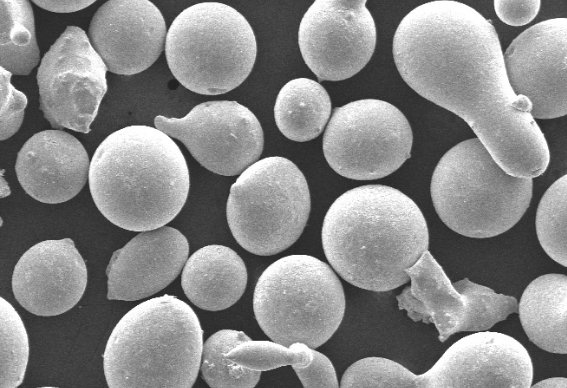

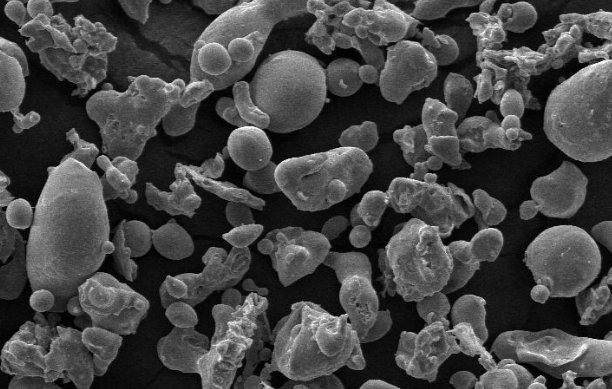

In order to be suitable for specific spraying methods such as cold spraying, it can also be prepared by gas atomization or water atomization. The morphology of nickel powder prepared by gas atomization is shown in Figure 2, and the morphology of nickel powder prepared by water atomization method is shown in Figure 2 3.

Fig. 1 Preparation of powder by liquid-phase precipitation

Figure 2 Powder prepared by gas atomization

The spraying methods that can be used for nickel powder: flame spraying, plasma spraying, supersonic flame spraying, explosive spraying, cold spraying. It is recommended to use powder produced by gas atomization or water atomization for supersonic flame spraying, explosive spraying and cold spraying.

Main use: Restoring and filling nickel or nickel-based alloy parts for worn or out-of-tolerance parts. For characteristic environments, wear and dimensional recovery of titanium alloy parts can also be repaired.

Coating performance: The prepared coating is hard and dense, has high bonding strength with the substrate, is easy to cut, and has good coating toughness, so thick coating can be sprayed, and the coating thickness can reach more than 1mm.

Price: According to the different milling methods, the particle size requirements are different, and the price is also different. The price of commonly used liquefied precipitation powder is 200 yuan/Kg. .

Hot information