current position:Information and data>Aluminum silicon (AlSi) powder

Main components of aluminum silicon powder: Si: 12.0%, Al balance.

Usual powder particle size: - 90+ 45μm.

Production method: aerosolization method.

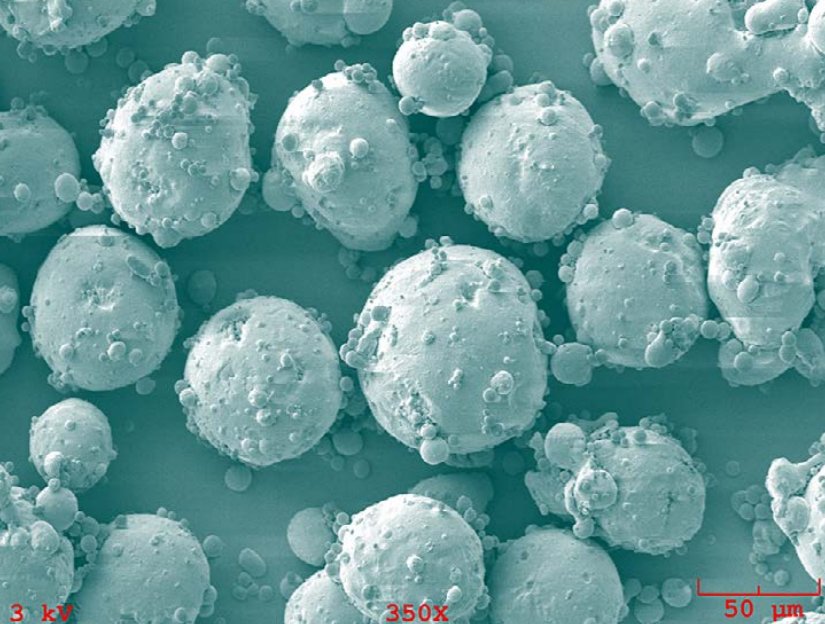

Powder morphology: nearly spherical, see Figure 1

Figure 1 Morphology of Al-Si powder (quoted from Oerlikon Metco DSMTS-0045)

Main application: It is the most common spraying material for repairing aluminum, magnesium and its alloy parts. Its coating has good bonding strength with aluminum, money, iron and other matrix materials, and is denser and harder than sprayed aluminum layers. It is thus easier to cut to a better surface roughness. It is commonly used in the repair of aluminum and magnesium components of jet engines and the repair of machining out-of-tolerance parts, and can also be used as brazing filler metal for aluminum and aluminum alloys. Its ultra-fine powder is also used to form composite powder with polyphenylester to prepare high-quality anti-friction coating with small friction coefficient.

Spraying method: Plasma spraying is usually used.

Coating properties: The bonding strength can reach 20MPa, the surface roughness is 12.5–25µm, the coating hardness is 120–130HV0.3, and the porosity is 4–12vol.%.

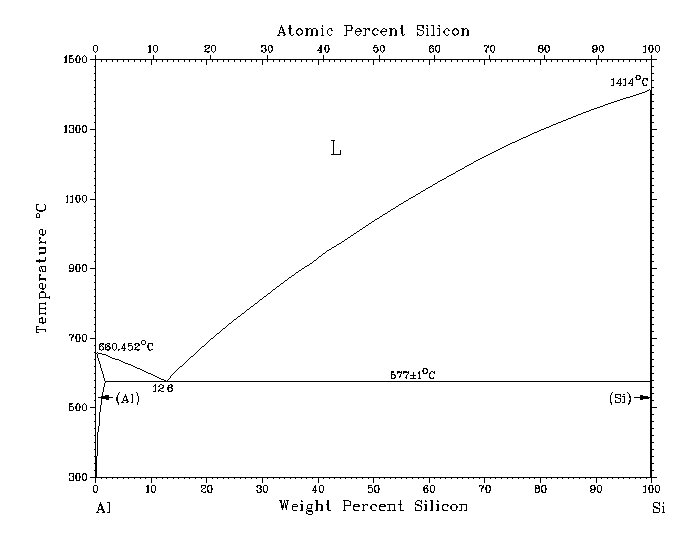

Aluminum silicon powder is a gas atomized powder of aluminum alloy alloyed with silicon element. Due to the addition of 12% Si, a simple eutectic system with low melting temperature is formed, as shown in Figure 2 for the phase diagram of Al-Si. Silicon reduces the melting temperature of aluminum-silicon alloy powder to 577°C (1071°F) while increasing fluidity, specific gravity and thermal expansion coefficient. It also reduces the shrinkage force that occurs when the spray particles solidify.

Figure 2 Al-Si phase diagram

Figure 2 Al-Si phase diagram

Hot information