current position:Information and data>Aluminum silicon boron nitride (Al8Si20BN) powder

The main components of aluminum silicon boron nitride powder: BN18~22%, Si7~9%, Al balance.

Commonly used powder particle size: -212 +22 µm.

Production method: mechanical wrapping. The composite powder material is composed of a number of agglomerated and coated particles. Each agglomerated and coated particle has hexagonal boron nitride as the core, and the aluminum-silicon alloy powder adheres to the surface of the core to form a coating layer. The content of each component is BN18-22%, Si7-9%, and Al balance. The aluminum-silicon boron nitride sealing composite powder material is composed of agglomerated and coated particles. The agglomerated and coated particles take hexagonal boron nitride as the core and adhere to the surface of the core to form a coating layer with aluminum-silicon alloy powder with uniform composition. , The characteristics of good spraying adaptability.

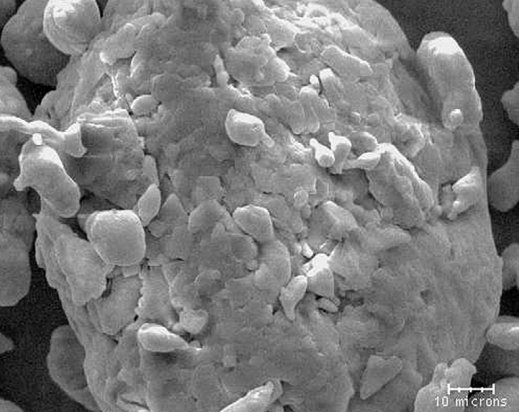

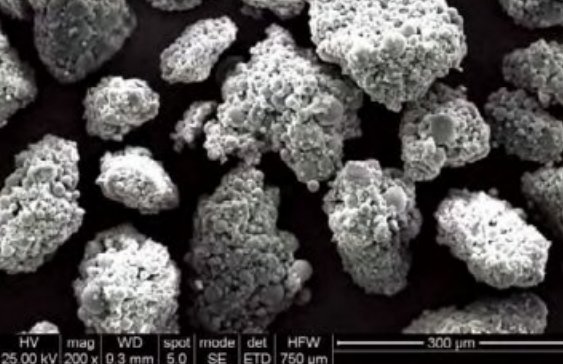

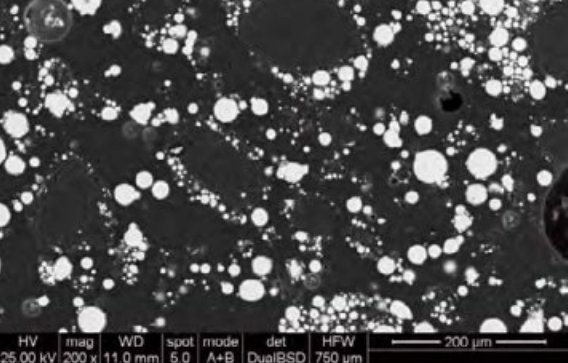

Powder morphology: nearly spherical, see Figure 1 for a single particle, and Figure 2 and Figure 3 for powder morphology and cross-section.

Figure 1 Morphology of a single powder particle

Fig.2 Particle morphology of AlSiBN powder

Figure 3 Cross-sectional view of AlSiBN powder

Main application: Aluminum silicon boron nitride has good corrosion resistance and abradability to various blade materials (including titanium alloys), and is used as abradable sealing coating to control the gap between the compressor blade and the casing, the maximum Minimize the wear of rotating parts and improve the efficiency of the air path. Aluminum silicon boron nitride coatings have good corrosion resistance and can be used in marine environments. Using hexagonal boron nitride as a lubricant has better stability than other abradable lubricants such as graphite.

Spraying method: Plasma spraying is usually used.

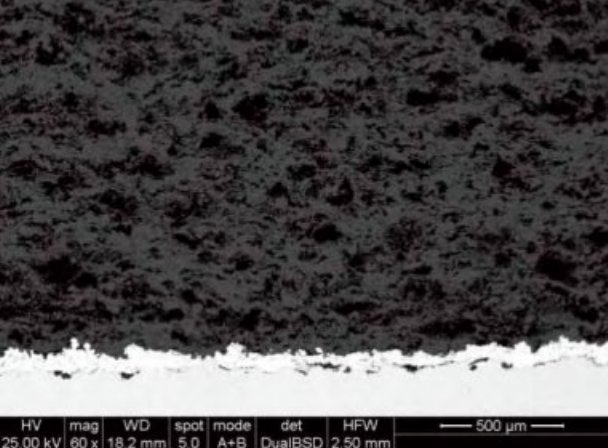

Coating performance: The bonding strength of the unsprayed bottom layer can reach 7MPa; the nickel-aluminum bottom layer is sprayed, and the aluminum silicon boron nitride is used as the surface layer, and the bonding strength of the coating can reach 10–17MPa; 25vol.%; the maximum service temperature is 450℃. See Coating 4 for the coating structure. The structure of the coating is uniform, mainly composed of the aluminum-based metal skeleton in the white part and the wearable hexagonal boron nitride in the black part. The coating contains some pores, and the aluminum-silicon as the bonding phase ensures that the coating has certain hardness, bonding strength, resistance to resistance. Erosion and other properties, the boron nitride phase provides wear reduction, anti-adhesion and self-lubricating properties.

Fig.4 Microstructure of AlSiBN coating

Hot information