current position:Information and data>Aluminum silicon graphite (Al6Si20C) powder

The main components of aluminum-silicon graphite powder: graphite>20%, Si5-7%, Al can be adjusted according to the graphite content. (Graphite has a lubricating effect and can be added according to the needs of the coating)

Commonly used powder particle size: -180 +10 μm.

Production method: mechanical wrapping.

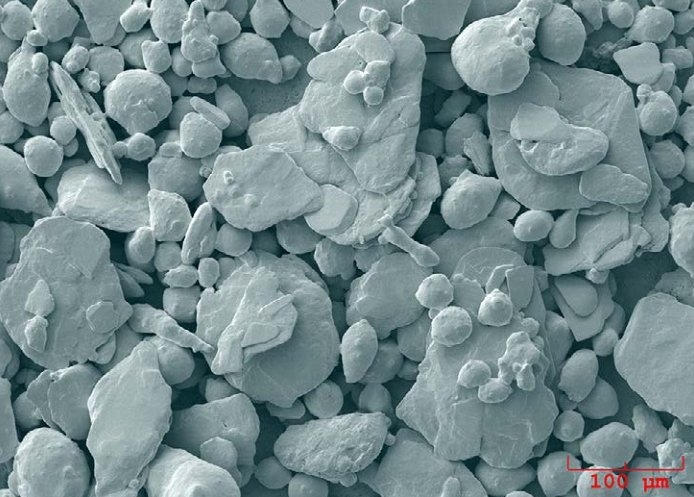

Powder morphology: mainly lamellar, mixed with nearly spherical, the powder morphology is shown in Figure 1.

Figure 1 Morphology of Al-Si-graphite powder (quoted from Oerlikon Metco DSMTS-0020)

Main application: As a wearable sealing coating, it is used to control the gap between rotor and stator components in aero-engine and gas turbine compressor components. Aluminum-silicon-graphite coatings are typically used in cryogenic applications with operating temperatures up to 415°C (780°F).

Spraying method: Plasma spraying and flame spraying can be used.

Coating performance: usually used in combination with the bottom layer, it is recommended to spray nickel-clad aluminum as the bottom layer, the coating bonding strength can reach 7-10MPa; the coating hardness is 55-80HRY15, the porosity is 15-25vol.%; the maximum service temperature is 415℃ . Long-term use in a high temperature environment will cause the aging of the aluminum alloy in the coating, resulting in a decrease in the hardness of the coating and a decrease in the bonding strength.

Hot information