current position:Information and data>Portal Preprocessing

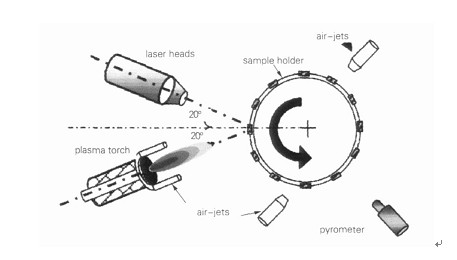

Treatment after plasma spraying: The obvious progress in the treatment process after plasma spraying is to use laser remelting technology. After the ceramic coating is formed by plasma spraying, laser plasma heating is immediately performed on the hot sprayed ceramic layer. Its working principle is shown in the figure. Show. Due to the characteristics of the plasma spraying process, the coating has a layered structure, high porosity and metastable phase in the coating, large residual stress on the metal/ceramic interface, and low bonding strength of the coating. These factors may The coating is easy to destabilize during use, resulting in shedding failure. After laser remelting, the ceramic coating can reduce the porosity, reduce the number of cracks, transform the metastable phase to the stable phase in the ceramic coating, and improve the surface hardness, wear resistance and thermal shock resistance of the coating.

Treatment after plasma spraying: The obvious progress in the treatment process after plasma spraying is to use laser remelting technology. After the ceramic coating is formed by plasma spraying, laser plasma heating is immediately performed on the hot sprayed ceramic layer. Its working principle is shown in the figure. Show. Due to the characteristics of the plasma spraying process, the coating has a layered structure, high porosity and metastable phase in the coating, large residual stress on the metal/ceramic interface, and low bonding strength of the coating. These factors may The coating is easy to destabilize during use, resulting in shedding failure. After laser remelting, the ceramic coating can reduce the porosity, reduce the number of cracks, transform the metastable phase to the stable phase in the ceramic coating, and improve the surface hardness, wear resistance and thermal shock resistance of the coating.

Hot information