current position:Information and data>Development of Thermal Spray Materials

In order to maintain sustainable economic development and reduce resource consumption, China began to build a circular economy and a conservation-minded society after entering the new century. The "4R" development principles (Reduce reduction, Reuse reuse, Recycle recycling, Remanufacture remanufacturing) on the construction of China's circular economy are put forward, and remanufacturing is the most dynamic part of the circular economy. Thermal spraying technology is a very important technology in the field of remanufacturing. It can prepare a variety of functional coatings such as wear resistance, corrosion resistance, heat insulation, electrical conductivity, insulation, wear reduction, lubrication, radiation protection, etc. It is widely used in modern industry and has achieved significant social and economic benefits.

Thermal spraying material is an important part of thermal spraying technology. It forms the main body of thermal spraying technology together with thermal spraying process and thermal spraying equipment. Thermal spraying technology has been around for nearly a hundred years since Dr. M.U.Schoop in Switzerland completed the original molten metal spraying device in 1910. During this period, flame spraying, arc spraying, explosive spraying, plasma spraying, supersonic flame spraying, high-speed arc spraying, supersonic plasma spraying and cold spraying technology appeared successively. Thermal spraying materials are also developing continuously with the development of equipment and technology. Looking back on history, the development of thermal spray materials has generally gone through four stages.

The first stage is mainly characterized by powders and wires with metals and alloys as the main components. Early powder materials were mainly produced by primary milling methods such as crushing and mixing, while wire rods were produced by drawing process to produce metal wires or alloy wires of a certain diameter. The types of materials are also relatively simple, mainly some metals and their alloys, such as aluminum, zinc, copper, nickel, cobalt and iron. The coating function is relatively single, generally anti-corrosion and wear resistance, and the application surface is relatively small. The spraying processes used for these materials are only powder flame spraying, wire flame spraying and arc spraying.

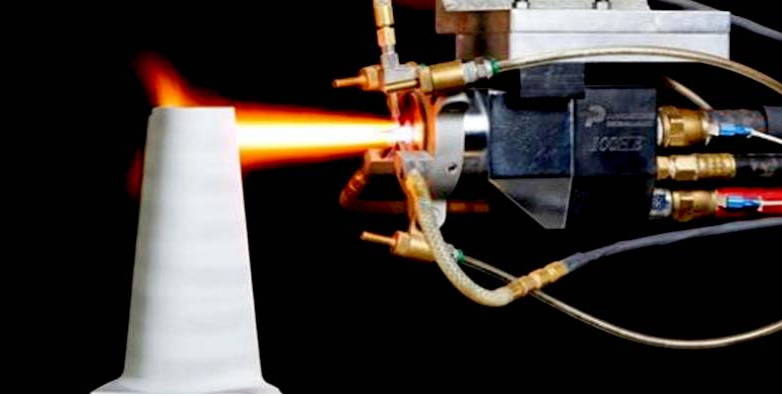

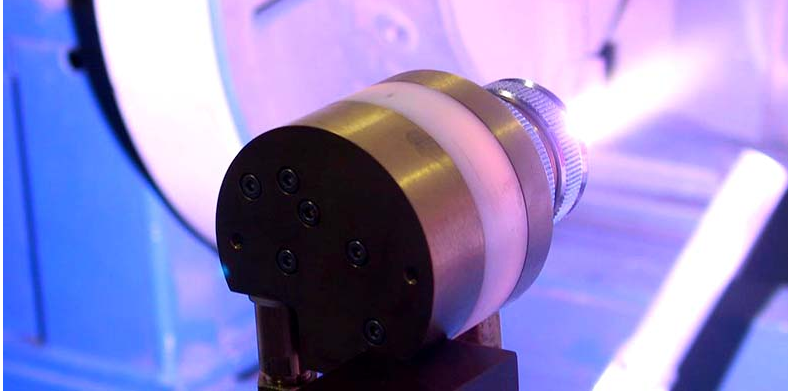

The second stage is mainly characterized by self-fluxing alloys. In the mid-1950s, it was found that in order to solve a large number of wear problems in industrial equipment, it was necessary to improve the process and produce more wear-resistant coatings. After several years of hard work, self-fluxing alloys have come out and the flame spray welding process has been developed, which is the famous "hard surface technology". Self-fluxing alloys are made by adding elements such as B, Si, and Cr, which can form low-melting eutectic alloys and anti-oxidation elements, into Ni, Co and Fe-based metals, and then heating and remelting after spraying to obtain a hard surface coating. This technology is inspired in part by the welding overlay process. Due to their high hardness, high metallurgical bond and very good oxidation resistance, these coatings have taken a big step forward in terms of wear and oxidation resistance. The emergence of self-fluxing alloys has played a huge role in promoting thermal spraying technology. Another technological breakthrough at this stage was the advent of plasma spraying equipment. The plasma flame temperature is as high as 10,000 degrees, and almost all materials with physical melting point can be sprayed. Therefore, some ceramic and cermet materials with high wear resistance, high temperature resistance, gas corrosion resistance and heat insulation properties can be used as thermal spraying materials, so that thermal spraying technology begins to move from simple maintenance workshops to aviation, aerospace, etc. high-tech industries, and solve a large number of material problems that are a headache for metallurgical engineers. Not only has it reassured aircraft designers who were concerned that adopting this technology would knock the plane out of the sky, but since then, there are hundreds of parts in an aero engine that have been incorporated into specifications that have to be heated. Only the spraying technology can meet the requirements of the designers.

The third stage is mainly characterized by the development of composite materials. In the mid-1970s, a series of composite powders and self-adhesive primary spraying powders appeared, and in the 1980s, it was mainly marked by the entry of sandwich welding wires as arc spraying materials into the market. Through the "composite" of material composition and structure, the improvement of spraying process and the improvement of coating performance are achieved. Nickel-coated aluminum and aluminum-coated nickel composite powder replace the traditional Mo wire, which improves the adhesion of the bottom layer; the self-adhesive primary powder combines the dual functions of the primer powder and the working powder, which simplifies the spraying process. After the metal or ceramic that is afraid of oxidation or nitridation is wrapped by Ni or Co, it not only protects the core components, but also chemically or metallurgically reacts with the core components, giving the coating better performance. Composite materials are not limited to powder, and composite spray filaments have also appeared in wire. In particular, filled composite wires have begun to enter the market. These composite wires can be sprayed with wire flames, but mainly by arc spraying, so that these processes, which can only form metal-alloy coatings, can be sprayed with ceramic hard coatings. The point of hard wear-resistant material greatly expands the application surface of the coating.

The fourth stage is mainly characterized by soft wire materials and nanomaterials. In order to overcome the shortcomings of powder spraying, it has been very early to smelt and roll powder into wire rods for spraying. However, there are many materials that cannot be rolled into wire rods. After that, powder core wire was produced, that is, the powder was wrapped in steel skin for spraying, which could be sprayed with flame or arc. But there are many poorly conductive powders or non-conductive materials that cannot be arc sprayed. At the same time, the material composition of the steel skin is also mixed into the coating, and the uneven melting of the powder core wire directly affects the quality of the coating. The French SNMI company changed the sheath material to plastic to make a flexible cord. The plastic material volatilizes during the spraying process (about 400 ° C) and does not participate in the coating, and all materials that can be used for thermal spraying can be made into flexible cords , which is the progress and new development in the morphology of thermal spraying materials

Nanomaterials refer to solid materials composed of extremely fine grains with a characteristic dimension size of <100 nm. Since the birth of nanomaterials, various nanomaterials including metal, non-metal, organic, inorganic and biological have been prepared. Due to its many mesoscopic properties different from microscopic and macroscopic substances, it has become a very challenging research field in the frontier of scientific and technological development. The same material, when the size is reduced to the nanometer scale, exhibits much higher hardness than the matrix phase material due to the limited sliding of dislocations, and its strength and hardness can be increased by 4 to 5 times. Nanomaterials have a large amount of interface, and the arrangement of atoms at the interface is chaotic. When atoms are deformed by external forces, they are easy to migrate and diffuse, showing very good plasticity, toughness, ductility, high strength, high plasticity and even superplasticity. Nanomaterials, It is of special significance for the surface modification of materials. In its development process, surface engineering needs nanomaterials with many characteristics to promote its development.

Hot information