Last time, I introduced the advantages and basic characteristics of yttrium oxide powder. This article will explain how to do pretreatment after getting the raw materials.

Many people who are new to thermal spraying will be very puzzled, why not spray directly with yttrium oxide powder? Since your last article said that yttrium oxide is so good, how can you use this powder to make another powder and then spray it?

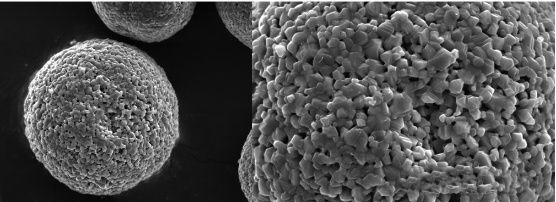

First of all, there are two pictures, one is the SEM of the raw material powder bought from the rare earth company before processing, and the other is the SEM of the thermal spray powder that our company has finished.

Raw powder under electron microscope

It can be seen that the powder before processing is flaky, the powder after processing is spherical particles, and the size is relatively equal, and observing the spherical surface, they are all raw powders (the more you look, the more crispy you look like a soldier), you can understand that we Take the broken instant noodle slag to make a spherical instant noodle slag ball.

Spherical spray powder under electron microscope (2000x and 5000x)

This treatment is to heat the powder uniformly in the later stage, so that the powder is melted evenly, and a coating surface with a smoother and less porosity is sprayed.

In order to achieve a perfect spherical powder, first "kneading" is required. That's the ingredient mentioned in the title.

==Ingredients==

Preparations: solvent, powder, batcher

Different types of powders are produced, and the solvents added are also different. Some people may ask, can you tell me what to add? Hmm... This is a commercial secret. Although I can't tell what was added, I can talk about the type and function of the added things.

Solvents are basically divided into three categories: water system, alcohol series, and other organic solvents

Main functions: to fully disperse the raw material powder, to better combine the raw material powder, to adjust the pH, and to adjust the concentration of the slurry

The dispersion and combination mentioned above seem to be opposite operations, but in fact, the stages of addition are different, so the effects are also different.

Rough steps: add the above-mentioned raw materials and other ingredients for mixing -> the purpose is to adjust the viscosity and temperature of the liquid, and adjust as needed

The degree of dispersion of raw materials

This step is called a slimy mix.

Hot information