The selection method of the die material of the reducing machine The correct selection of the die material of the reducing machine, the rational design of the shape and size of the die hole, the rational formulation of the die structure and repair process, and the fine processing of the drawing die are of great significance to the production of steel wire.

Reducer die material: Due to the limitation of wire drawing working conditions, the reducer die material must not only have high hardness and wear resistance, but also sufficient strength (compressive strength and bending strength), toughness and very smooth work. surface. At the same time, it is necessary to consider the corrosion and oxidation of various lubricants and various coatings, including the atmosphere, requiring small adhesion to the surface of the steel wire, small expansion coefficient, high thermal conductivity, low price, and convenient processing. At present, carbide wire drawing dies are mainly used for steel wire production.

An alloy formed by pressing and sintering after mixing. At present, cemented carbide is mainly divided into three categories: W-Co, W-Co-ti and W-Co-ta-ti. Due to the brittleness of the latter two alloys, they are not suitable for use as drawing dies. Correct selection of wire drawing die materials, reasonable design of the shape and size of the die hole, reasonable formulation of the die structure and repair process, and accurate and accurate processing of the wire drawing die are of great significance to the production of steel wires.

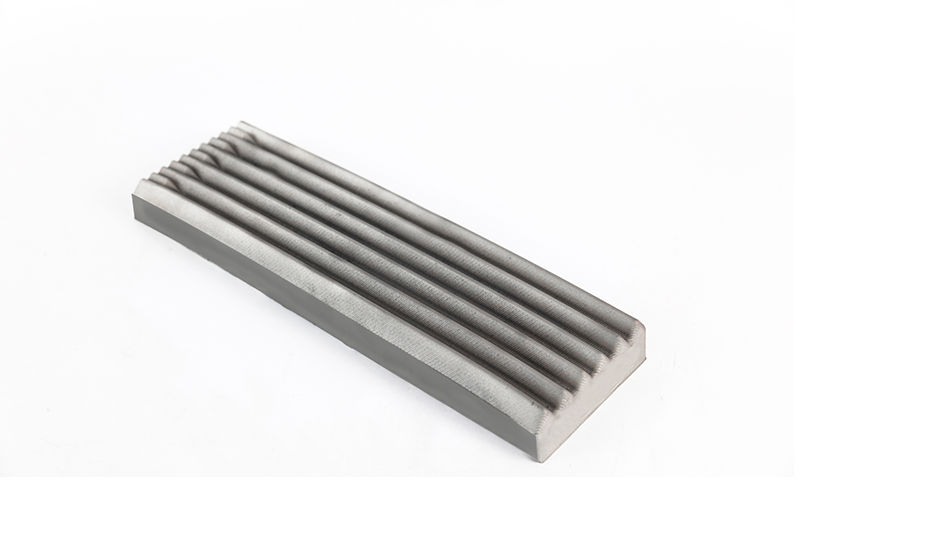

1. Features of cemented carbide materials: cemented carbide is an alloy made of refractory metal cemented carbide as aggregate and cobalt as binder, using powder metallurgy method, pressing, molding, and sintering after mixing. At present, cemented carbide is mainly divided into three categories: W-Co, W-Co-ti and W-Co-ta-ti. Due to the brittleness of the latter two alloys, they are not suitable for use as drawing dies.

2. Die material for diameter reducing machine: Due to the limitation of wire drawing conditions, the wire drawing die core material must not only have high hardness and wear resistance.

In addition, it should have sufficient strength (compressive and flexural strength), toughness and a very smooth working surface. At the same time, factors such as adaptability to various lubricants, corrosion of various coatings, oxidation containing the atmosphere, low adhesion to the surface of the steel wire, low expansion coefficient, high thermal conductivity, low price, and convenient processing should also be considered. At present, carbide wire drawing dies are mainly used for steel wire production.

(1) Strong polishing force and low adhesion. By processing the above-mentioned surface roughness, not only the drawing quality of the steel wire surface is ensured, but also the power consumption in the drawing process is reduced due to its small friction coefficient.

(2) The thermal conductivity is only 0.14 ~ 0.21cal/cm degree. Two, heat can be transferred during the stretching process.

(3) High hardness and good wear resistance. The room temperature hardness is generally between hra86 and 93, and the necessary red hardness is necessary; the hardness can be kept below 500 ℃.

Hot information