current position:Information and data>Thermal Barrier Coating

Thermal Barrier Coatings (TBC for short) is a ceramic coating, which is deposited on the surface of the base material of high temperature resistant metals or superalloys to insulate and reduce the temperature of the base, so that the parts made of (such as engine turbine blades) can operate at high temperatures, and can improve the thermal efficiency of components (engine, etc.) by more than 8%.

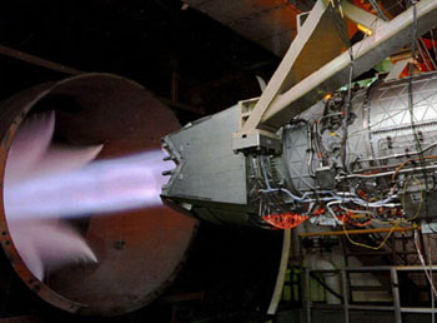

The concept of thermal barrier coating was first proposed in the 1950s. After a long period of exploration in the material selection and preparation process of the coating, a major breakthrough was made in the early 1980s, laying a solid foundation for the application of thermal barrier coatings. With a solid foundation, with the application of thermal barrier coatings on hot-end components of high-temperature engines, Western countries have recognized the extraordinary value of thermal barrier coatings and began to increase their research and development efforts. With the development of aviation, aerospace and civil technology, the temperature requirements of hot-end components are getting higher and higher, which has reached the limit of superalloys and single crystal materials. Taking the heated parts of gas turbines such as nozzles, blades, and combustion chambers as an example, they are in harsh environments such as high-temperature oxidation and high-temperature airflow erosion. , so it is very susceptible to damage. The advent of thermal barrier coatings protects high-temperature hot components, and thus enables aero-engines and industrial gas turbines to work at higher temperatures, thereby improving the efficiency of these important facilities.

With the development of aviation, aerospace and civil technology, the temperature requirements of hot-end components are getting higher and higher, which has reached the limit of superalloys and single crystal materials. Taking the heated parts of gas turbines such as nozzles, blades, and combustion chambers as an example, they are in harsh environments such as high-temperature oxidation and high-temperature airflow erosion. , so it is very susceptible to damage. The advent of thermal barrier coatings protects high-temperature hot components, and thus enables aero-engines and industrial gas turbines to work at higher temperatures, thereby improving the efficiency of these important facilities.

wococarbide.com provides equipment and materials for thermal barrier coatings, and can also spray and process thermal barrier coatings for customers. wococarbide.com has accumulated a lot of relevant experience in thermal barrier coatings in the past spraying practice. Through the improvement of the underlying technology and the improvement of coating materials, coupled with the advanced spraying equipment and technology, it can create reliable spraying quality for users.

Today, the professional equipment produced by wococarbide.com has been applied in domestic aircraft engine manufacturing enterprises in China. The nano zirconia materials we produce have also been proved by thermal shock experiments to surpass imported products. If you are interested in thermal barrier coating equipment, material products or processing services, you are welcome to "register" as a member of this website, and wococarbide.com will then provide you with detailed solutions.

Hot information