As we all know, in the process of metal powder spraying, the powder coating is fluidized and transported to the spray gun through the air flow. The spray gun passes through the high-voltage electrostatic generator to generate corona discharge at the electrode needle of the spray head, and a dense negative charge is generated near the electrode, and the powder is discharged from the gun head. When ejected, the captured charges become charged powder, which flies to the grounded workpiece under the action of airflow, electric field and its own gravity, and is adsorbed on the surface of the substrate. Therefore, in our spraying process, we need to take adequate precautions. This editor of wococarbide.com metal spraying will take you to understand the precautions of metal spraying technology.

1. Coating method of metal powder spraying

In most cases, the electrostatic spray gun is used for spraying. Since this type of product contains metallic pigments, the system should be well grounded when spraying with the electrostatic gun. fire phenomenon. The effect of forming the coating film has a lot to do with the setting, quality or brand of the spray gun. After a long time of spraying, a large amount of metal powder may accumulate at the discharge needle of the spray gun, and the sprayer needs to clean the discharge needle regularly.

2. The gloss of metal powder coating

In most cases, due to the large error, it is not recommended to use a gloss meter to measure the gloss of the metal appearance coating film, but only use the visual comparison method to judge whether it is consistent with the standard sample.

3. Recyclability of metal powder coatings

For powders produced by the dry blending method, since separation occurs during the spraying and recycling processes, there will be a certain difference in the metal pigment content between the recycled powder and the new powder, which may lead to inconsistent appearance of the coating film and color cast. . This is due to the difference in properties between metallic pigments and powder particles. .. It is recommended that the ratio of recycled powder to new powder be at least 1:4. If the powder coating produced by the bonding method is used, since the ratio between the metallic pigment and the powder particles is relatively fixed, the recycled powder can be completely reused.

4. Overcoat layer of metal powder coating

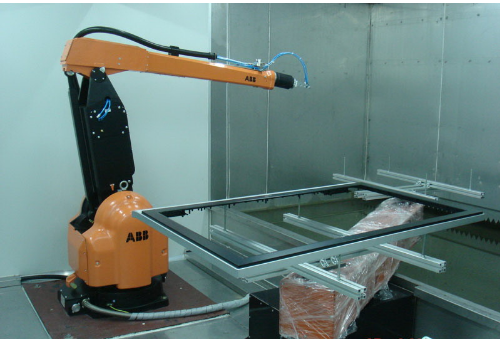

Re-spraying an overcoat layer on the metal powder coating has the following advantages: enhancing the stone-strike resistance of the metal powder coating; increasing the aesthetic effect of the metal powder coating; completely solving the wipeability of the metal pigment; improving the metal powder coating. of weather resistance. In order to improve the appearance of the glossy layer, it is required that the workpieces that have been sprayed for .. times should not be polluted in any way. Therefore, a fully automated spraying line and two independent spray booths are generally required for separate spraying. In general, it is recommended not to spray the overcoat layer.

5. Erasability of metallic pigments

Neither dry-blending nor adhesive-fixing powders can completely solve the problem of wipe-off of metallic pigments. The solution to the wipe-off property is to spray a clear coat on the metal powder coating film.

6. Try to keep the spraying conditions as stable as possible

Use the same set of spraying equipment, use the same voltage, air pressure and other parameters; try to keep the distance between the spray gun and the workpiece unchanged, and try to maintain the stability of the film thickness; the powder coating has been fully fluidized before spraying; when using recycled powder, the recycled powder should be The ratio of new powder should be at least 1:4; try to avoid using metal powder coatings to spray workpieces with complex shapes or deep depressions; it is recommended that multiple workpieces to be assembled together should be sprayed at the same time.

Hot information