1. Introduction of nickel-based amorphous self-fluxing alloy powder (MRC-70) coating

The chromium of the nickel-based amorphous self-fluxing alloy powder (MRC-70) coating can form an oxide film on the surface of the coating to protect the matrix material, so that the nickel-based amorphous self-fluxing alloy powder (MRC-70) coating has good performance. Anti-oxidation ability, the molybdenum in the coating can provide good anti-reduction ability to the material. In addition to good oxidation resistance and reduction ability, nickel-based amorphous self-fluxing alloy powder (MRC-70) coating also has excellent resistance to pitting corrosion, crevice corrosion and stress corrosion cracking. Therefore, nickel-based amorphous self-fluxing alloy powder (MRC-70) coating is considered to be a multifunctional corrosion resistant coating.

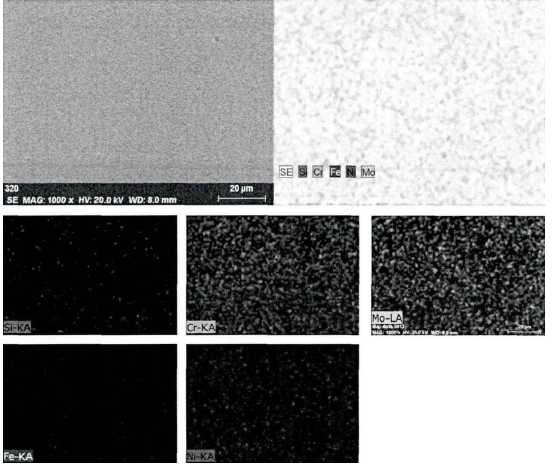

2. The original morphology analysis of nickel-based amorphous self-fluxing alloy powder (MRC-70) coating

(as the picture shows)

A comprehensive scan of the uncorroded nickel-based amorphous self-fluxing alloy powder (MRC-70) coating is carried out. It can be seen from the surface scan that the distribution of various elements on the surface is uniform, mainly containing three elements of Ni, Cr, and Mo. A large number of studies have been carried out. It is shown that the nickel-based amorphous self-fluxing alloy powder (MRC-70) coating has good intergranular corrosion resistance and oxidative corrosion resistance, and the Fe content in the coating is low, mainly passivation series metal elements, on the surface of the coating. A passivation film can be formed, so the coating has good corrosion resistance under normal temperature conditions. The nickel-based amorphous self-fluxing alloy powder (MRC-70) coating is mainly Ni-based solid solution, and the content of Fe and C is small.

Hot information