current position:Information and data>How to do the metallography of thermal spray coating

I haven't done the metallographic examination of the coating. I saw that there is a standard for metallographic testing in the forum. I feel that it is very different from the metallographic examination of metal materials.

The metallographic and metal materials of the coating are very different. One is that the sample preparation is very different, and the other is that the items of tissue observation are very different.

1. Different sample preparation

Compared with metal materials, the sample preparation of coatings is more difficult. Although the sample preparation process is the same, there are basically four steps: cutting - cleaning - mounting - grinding and polishing. Most coatings do not require corrosion. But because the properties of different kinds of coatings vary widely, each process differs in detail from metallic materials.

1. Cutting

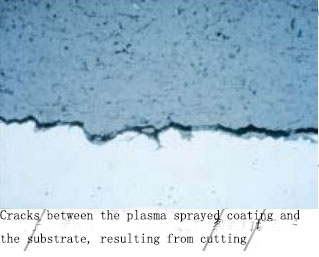

The cutting of metallographic samples usually adopts wire cutting and grinding wheel cutting. For non-conductive coatings, wire cutting cannot be used, and only grinding wheel cutting can be used. When cutting, the relative cutting direction of the coating position must be considered, that is, to ensure that the rotation direction of the grinding wheel is in the direction of the coating to cut the sample, and the coating is subjected to pressure during cutting. Failure to do so will cause the coating to separate from the substrate.

mosaic

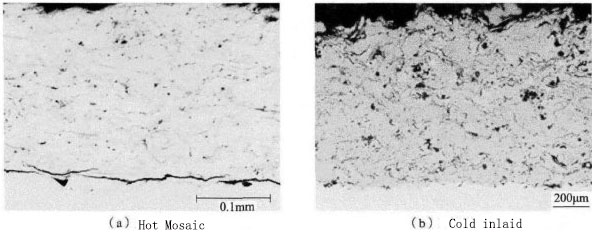

This process is particularly important, and the inlay of metal materials can generally be hot inlaid. However, the inlay of the coating is generally recommended to use cold inlay, and only very dense coatings and coatings with high bonding strength are allowed to use hot inlay. For porous seal coats, vacuum mounting is required

4. Grinding and polishing

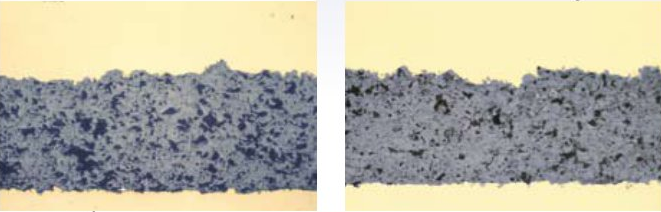

Coating grinding and polishing generally use different grinding and polishing parameters according to the type of coating, otherwise it will lead to misjudgment of coating porosity and so on.

2. Different testing purposes

Metal materials generally detect the grain size of the organization, non-metallic inclusions, etc. The metallographic inspection of thermal spraying generally checks the porosity of the coating, the content of oxides, whether it is separated from the metal, and the interface contamination. content

Too much will not be detailed here. If you are interested, you can leave a message to continue the discussion.

3. Mosaic

This process is particularly important, and the inlay of metal materials can generally be hot inlaid. However, the inlay of the coating is generally recommended to use cold inlay, and only very dense coatings and coatings with high bonding strength are allowed to use hot inlay. For porous seal coats, vacuum inlays are required.

Hot information