Boiler furnace spraying, thermal spraying, boiler anti-wear spraying, boiler anti-corrosion spraying, supersonic arc spraying, boiler heating surface anti-wear and anti-corrosion spraying, boiler water wall anti-wear spraying, deflector anti-wear, anti-wear plate installation, boiler deflector Installation, latitude and longitude anti-wear

1. Principle of supersonic spraying

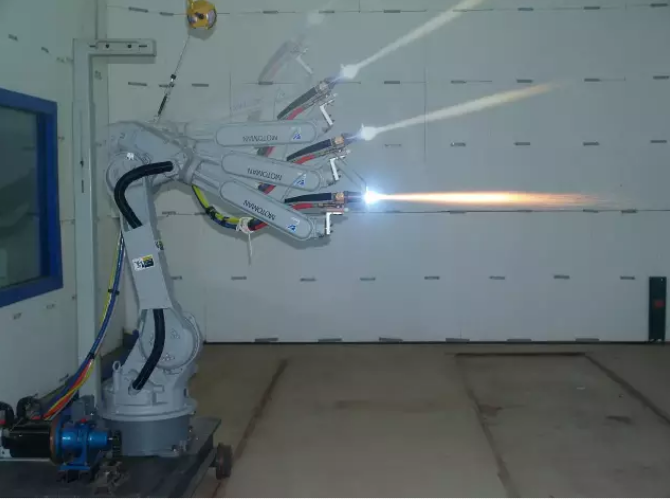

The principle of arc spraying is to use two continuously fed metal wires as consumable electrodes, generate arcs at their ends as a heat source, use compressed air to atomize the molten wire, and spray it onto the workpiece at supersonic speed to form a Thermal spray method for high bond strength, low porosity and low surface roughness coatings. Its working principle is the same as that of ordinary arc spraying (subsonic atomization), and supersonic arc spraying is a continuous melting-atomizing-deposition process. However, in terms of atomization, there is a fundamental difference between supersonic arc spraying and ordinary arc spraying, that is, supersonic arc spraying uses supersonic atomization. Its advantages are: good atomization effect, fine and uniform particles after atomization, and fast speed, which is conducive to obtaining high-quality coatings. Supersonic arc spraying uses a Laval nozzle to increase the air velocity from subsonic to supersonic, which enhances the acceleration effect of the air on particles, thereby increasing the particle velocity. Particle velocity has a large effect on the performance of the coating. When the particle velocity is high, the impact of the particles on the substrate during deposition is strong, and the particle deformation is sufficient. Facilitates the bonding of particles to substrates and particles to particles, thereby improving the bonding strength and cohesive strength of the coating; the particle velocity is high, the flight time of the particles in the air before deposition is short, and less oxides are produced during the flight. . It is beneficial to the bonding of particles, thereby improving the cohesive strength of the coating and reducing the porosity of the coating. The higher the particle velocity, the more favorable it is to obtain a high-quality coating.

With the upgrade of thermal spray equipment, the particle velocity continues to increase, and the coating quality also continues to improve. Supersonic atomization reduces the particle size and roughness of the coating. Roughness is an important performance index of the coating and depends on the particle size after atomization. The supersonic atomization enhances the effect of the airflow on the molten metal at the end of the welding wire, and the atomized particles are fine and uniform, which greatly reduces the roughness of the coating. At the same time, the reduction of particle size also reduces the splash during the particle flattening process, which is beneficial to reduce the porosity of the coating. Supersonic atomization is the starting point of supersonic spraying, and it is the fundamental difference between it and ordinary arc spraying. Supersonic arc spraying equipment includes power supply, spray gun, wire feeding mechanism and its accessories. The key equipment is supersonic spraying. Our company adopts imported nozzles, and the spraying current is stable. On the premise of ensuring the atomization effect of the wire and the quality of the coating, the spraying area of 20 square meters per day can be achieved. During arc spraying, the temperature of the arc zone is as high as 5000-6000℃, and the nozzle is cooled by air cooling.

Second, the technical advantages of supersonic spraying

Compared with ordinary flame spraying, supersonic spraying has the following technical advantages:

1. High thermal efficiency. Most of the heat generated by flame spraying is lost to the atmosphere and cooling system, and the utilization rate of heat energy is only 8-15%. Arc spraying directly converts electrical energy into thermal energy to melt the wire, and the thermal energy utilization rate is as high as 70-80%.

2. High production efficiency. The production efficiency of arc spraying is high, which is reflected in the fact that there are many metal wires sprayed per unit time. In general, its production efficiency is more than 8 times that of flame spraying.

3. Simple operation, safe and reliable. The arc spraying equipment does not have a complicated operating mechanism. As long as the working current and voltage are selected within the specified range according to the different spraying materials, the spraying quality can be guaranteed. Only electric energy and compressed air are used on site, and flammable gases such as oxygen and acetylene are not used, which is safe and reliable.

4. The coating has high bonding strength. Arc spraying can achieve higher bonding strength without increasing the working temperature and without using precious metals, generally up to 20MPa, which is 2.5 times the strength of flame sprayed coatings. The bonding strength of the supersonic arc spray coating can reach 60MPa, which is close to the quality of the plasma.

5. The coating porosity is low. The porosity of the coating surface is generally less than 1%, which improves the wear and corrosion resistance of the coating. Due to the unique advantages of supersonic arc spraying, it has been widely used in the fields of material anti-corrosion, wear-resistant, repairing and recycling, and power production, resulting in great economic and social benefits.

The development and expected success of supersonic arc spraying shows that the technology is highly advanced and scientific. The specific performance is as follows:

1. By applying aerodynamic principles, computer design and Laval nozzles and other means, the supersonic arc spray gun has been successfully developed, which greatly improves the particle speed. The measured particle speed exceeds the current domestic and foreign arc spray particle speed. The maximum speed is 385.7m/s.

2. The designed supersonic arc spraying power supply has reliable arc starting, and the acceleration effect of the Laval nozzle on the airflow, which elongates the arc and keeps the arc stable, effectively improving the atomization effect of the wire particles and the coating quality. Density and bond strength.

3. The spray gun is air-cooled, which solves the bonding problem between metal particles and the inner wall of the nozzle, improves the quality of the air flow, and improves the speed of the particles and the quality of the coating.

Hot information