current position:Information and data>Quality Inspection of Thermal Spray Ceramic Coatings

1. What are the inspection items and inspection methods?

1.1 Appearance

Visual inspection, the effective surface should be uniform in color, and no cracks, bumps, weak bonding, adhesion of foreign objects or other defects that are harmful to use are allowed.

1.2 Thickness

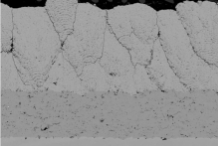

Use a measuring tool to directly measure the thickness of the coating, or use the metallographic method to measure the thickness of the cross section of the coating, or use a non-destructive thickness gauge to measure. Execute according to the provisions of GB/T 11374-2012. The thickness should meet the requirements of the agreement.

1.3 Bonding strength

The bonding strength of the coating and the substrate shall be tested according to GB/T 8642-2002 and shall meet the requirements of the agreement.

1.4 Hardness

The hardness of the wear-resistant ceramic coating shall be measured according to the provisions of GB/T 9790-1988 and shall meet the requirements of the agreement.

1.5 Porosity

The porosity of the corrosion-resistant coating after sealing is checked according to the iron reagent method, and the surface of the coating should have no pores leading to the substrate.

1.6 Thermal shock resistance

The thermal shock resistance of the heat-resistant coating shall be tested according to the following method, and the coating shall not be cracked, peeled off or lifted.

Test method: Use the product as the sample, or use the same material and prepare the sample under the same conditions as the product. The size of the substrate is 50mm long, 50mm wide, and 5-6mm thick. Adjust the test temperature, that is, 800 degrees Celsius for alumina and 900 degrees Celsius for zirconia. Then, the sample and the bracket are put into a heating furnace for heating, and after reaching the temperature, they are kept for 10 min and taken out, and then put into cold water at room temperature together. Observe whether the surface coating of the sample is cracked, peeled or lifted. Heating Shanghai with a resistance furnace, the temperature fluctuation range is ± 5 degrees Celsius. The bracket is preferably made of stainless steel as the bracket and with stainless steel wire mesh as the support surface.

1.7 Other properties

Other properties of the ceramic coating, such as friction coefficient, emissivity, dielectric coefficient, requirements for microstructure, etc., can be tested according to the methods specified in the agreement.

2. What are the required inspection items?

All ceramic spray coatings, in addition to the appearance must meet the requirements of 1.1, according to their different applications, it is recommended to check the following related items according to the agreement.

2.1 Ceramic coatings for wear resistance

Inspection of thickness, bond strength and hardness is required. Follow the provisions of 1.2, 1.3 and 1.4 respectively. and meet the requirements.

2.2 Ceramic coatings for corrosion resistance

Inspection of thickness, bond strength and porosity is required. Follow the provisions of 1.2, 1.3 and 1.5 respectively, and meet the requirements.

2.3 Ceramic coatings for heat resistance

Requires inspection of thickness and thermal shock resistance. Follow the provisions of 1.2 and 1.6 respectively, and meet the requirements.

The article on this page is original, please inform us if you reprint it. If there is plagiarism, its shameful behavior will be cracked down.

Hot information