With the continuous upgrading of metal surface treatment technology, thermal spray aluminum technology has been widely used in product manufacturing and equipment maintenance. Most of the surface damage of marine equipment is caused by corrosion of seawater, liquid, gas, etc. Due to its high cost and inconvenient replacement, most companies choose metal surface treatment technology for surface repair and strengthening.

As a material with good anti-corrosion performance, aluminum is often used to prepare anti-corrosion coatings. The commonly used thermal spraying aluminum process has two methods: wire flame spraying and arc spraying. Before spraying, it is necessary to comprehensively consider the damage of the workpiece and on-site construction conditions to select a suitable thermal spraying process.

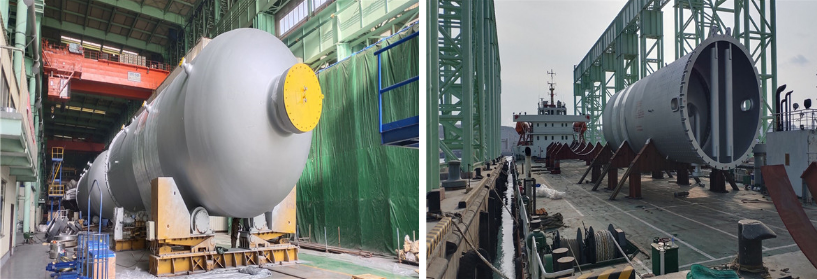

wococarbide.com's thermal spraying aluminum construction uses arc spraying technology to repair the surface of damaged workpieces. Oxygen-acetylene is used as the heat source, and aluminum wire is used as the spraying material. Before construction, the technicians emphasized that attention should be paid to the inspection of the system and equipment to ensure safe construction. After the spraying operation is completed, the coating needs to be sealed, which can make the aluminum coating more compact, further isolate the medium, and further protect the surface of the workpiece.

The choice of thermal spraying aluminum coating, in addition to having good protective function, can save costs and provide surface strength in terms of investment; in addition, compared with other spraying technologies, it has high bonding strength and good coating performance.

Hot information