The plunger rod is a commonly used workpiece in the petroleum industry, and its surface corrosion and wear are the main damage methods. There are many ways to repair the surface of the plunger rod, such as thermal spraying, surfacing, etc. With the continuous upgrading of metal surface technology and the continuous emergence of new technologies, laser cladding, as a new type of metal surface treatment technology, is widely used. More and more industries are paying attention.

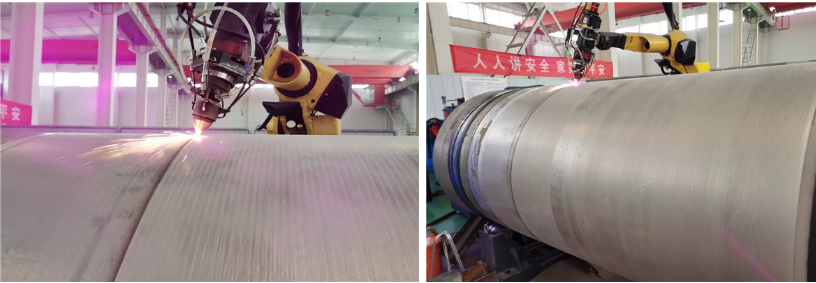

Today, wococarbide.com was entrusted by the customer to strengthen the surface of its large plunger rod with a diameter of 1200*2670. The coating thickness is >0.5mm, the hardness is >HRC45, and the coating should be well combined without pores, blisters, peeling and other phenomena. Before cladding, the technicians emphasized that the surface of the workpiece needs to be cleaned and inspected before laser cladding; during the cladding process, parameters such as temperature, powder feeding speed, voltage and power should be strictly controlled. In the parts with welded joints, it is necessary to carry out flaw detection to see if there are cracks and other phenomena. If found, it should be dealt with in time to ensure the quality of the cladding coating.

The main features of the application of laser cladding technology in metal surface repair are as follows:

1. The coating and the substrate are metallurgically bonded, the bonding strength is higher, the coating is denser, and the anti-stripping performance is better;

2. In the state of high-speed cladding, the heat input to the workpiece is small, so the workpiece is not easily deformed, which is conducive to improving the mechanical and corrosion resistance of the material;

3. The thickness of the laser cladding layer is controllable, and multi-layer cladding can be performed, and the use effect is more significant for workpieces with relatively high coating requirements;

4. Energy saving and environmental protection in the cladding process, which is one of the reasons why laser cladding technology is widely promoted.

In terms of laser cladding process, wococarbide.com not only has professional equipment, but also has experienced technicians, and has in-depth research on the laser cladding processing scheme of various workpiece surfaces. Customers are welcome to visit the factory.

Hot information