current position:Information and data>Thermal sprayed ceramic coating on the drum surface

Ceramic is a compound composed of metal elements and non-metal elements. Its characteristics such as strong organizational bonding force and dense accumulation give ceramic materials the characteristics of high melting point, high hardness, high chemical stability, and high insulation and heat insulation ability. The ceramic coating is prepared by combining the thermal spraying processing technology with the ceramic material, which can organically combine the characteristics of the ceramic material with the characteristics of the metal material, so as to obtain a higher performance protective coating.

For workpieces with relatively high production costs, such as rollers, thermal spraying technology is often used to prepare metal protective coatings on the surface to improve their surface performance. Compared with other metal coatings, the main features of thermal spray ceramic coating technology are as follows:

1. Ceramic materials have the characteristics of high temperature resistance, wear resistance and corrosion resistance, which can be organically combined with metal workpieces to exert better performance;

2. The ceramic coating can be prepared on a variety of substrates, and there are many types of materials that can be used to prepare the ceramic coating, and the coating preparation is convenient;

3. Different thermal spraying processes can be used for spraying, so as to obtain functional coatings with different properties such as wear resistance, high temperature resistance, corrosion resistance, oxidation resistance, insulation and heat insulation;

4. Limited by the size of the workpiece and the construction site, the coating preparation range is relatively wide.

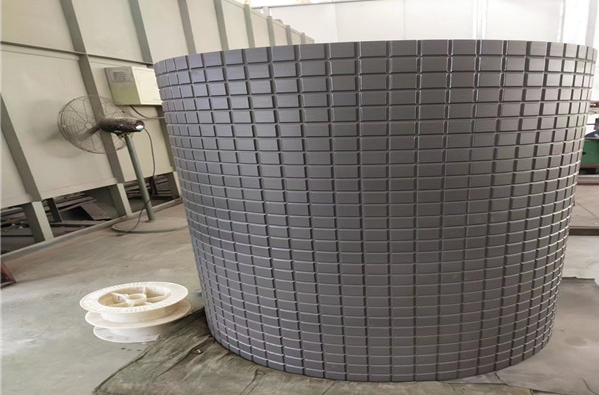

The properties of coatings prepared by different thermal spraying technologies are different. When wococarbide.comk repairs the surface of the drum, according to the requirements of its working conditions, the ceramic coating is prepared on the surface by the supersonic spraying process. The thickness of the coating after grinding is 0.15 mm, roughness Ra5-8, hardness HV1200, no peeling or peeling off of the coating.

When the surface of different workpieces is repaired, it is necessary to select corresponding spray materials to prepare metal protective coatings according to their damage and operating requirements. Generally, after the surface repair of damaged workpieces, the surface performance of the damaged workpiece is the same as that of the new workpiece. The performance is equal to or even higher than the surface strength of the new workpiece. Therefore, with the continuous development of the machinery industry, the application of thermal spray technology is also more and more extensive.

Hot information