Do you know what the sizing roller for amorphous thermal spray coating is? The anti-corrosion and wear-resistant coating processing factory tells you:

The sizing device of the paper machine in the paper mill consists of a coating roll and a chrome-plated roll. The performance of the sizing roller is directly related to the sizing effect of the paper. In order to improve the surface strength of paper and paperboard and prevent the diffusion and penetration of water-based liquids, it is necessary to carry out sizing treatment on paper and paperboard.

A Fourdrinier paper machine generally has seventy or eighty rubber rollers, which can be divided into smooth rollers (flat rollers with no pattern on the surface), grooved rollers (with grooves on the surface of the coating), and threaded rollers (covered). There are thread grooves on the surface of the rubber coating), vacuum rolls, movable arc rolls (hollow bending rolls) and medium and high rolls, etc., which are used for different parts of the paper machine to squeeze water, press, and calender. According to different functions, it can be divided into rubber press rollers and various auxiliary rubber rollers driven by the rubber press rollers. The rubber press rollers should be able to withstand high pressure and play the role of driving other auxiliary rubber rollers. The hardness requirements are high. 85°~95°. When the pulp is pressed through the upper and lower rolls, the pressure exerted by the upper roll (cast iron roll core, outsourcing brass or hard rubber) makes the water squeeze out, and the lower roll (ie, the press rubber roll) plays a supporting role.

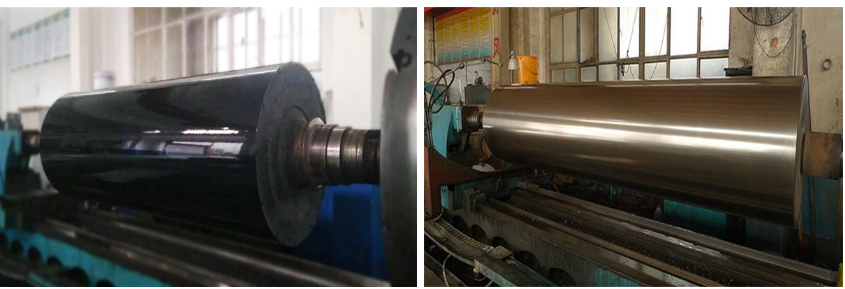

Because the rubber roller is relatively soft, a little hard object will be scratched during high-speed operation. Once scratches appear, it can no longer be used. Jinan Tianmeng New Material Technology Co., Ltd. researches and develops the amorphous coating for paper sizing rolls, the hardness of the coating is above HRC75, the temperature resistance can reach 800 ℃, the friction coefficient is greatly reduced, and the service time is more than 3 times that of ordinary chrome-plated rolls, reducing The replacement times of the rollers of the sizer improves the quality of the sizer and prolongs the service life of the related equipment. This process offers a number of benefits to the paper mill: The retention of the surface sizing agent is close to 100% and the use efficiency is high.

Hot information