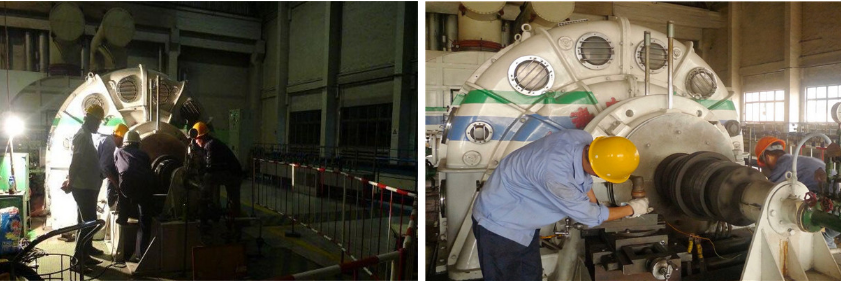

Thermal spraying technology to repair the worn parts of the generator slip ring:

Generators are one of the most important equipment in power plants. The slip rings of generators and exciters in thermal power plants are often rotated at high speed and are in close contact with carbon brushes. Along with mechanical vibration, long-term operation will cause wear on their surfaces. , The finish decreases, resulting in poor contact between the carbon brush and the surface of the slip ring, which will cause the generator slip ring to burn out, catch fire and other vicious accidents, and cause the slip ring to be scrapped and returned to the factory for maintenance. There are great hidden dangers for power plants. Using thermal spraying technology to spray technical coating on the surface of slip ring can effectively improve its wear resistance. The molten wire is atomized, and then sprayed to the surface of the workpiece at a high speed to form a metal coating. The metal coating prepared in this way has high density, low porosity, and a high degree of bonding with the substrate, which can effectively improve the surface resistance of the workpiece. Grinding performance, while reducing the surface roughness of the workpiece and improving its smoothness.

Hot information