The advantages of thermal spray ceramic coating in the paper industry:

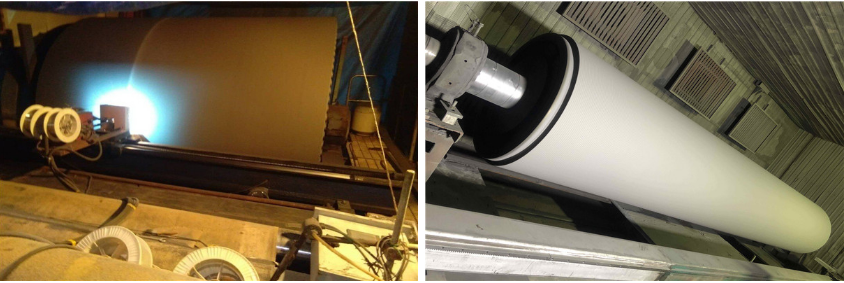

In the papermaking industry, the working environment of paper processing equipment is generally corrosive. In the case of high-speed mechanical operation, the high temperature resistance and wear resistance of the equipment are also required. However, the wear resistance and corrosion resistance of metal equipment is relatively high. It is said to be relatively poor, which will not only affect the quality of paper products, but also reduce the service life of the equipment. In addition, machinery and equipment in the papermaking industry work under high-speed, high-temperature, high-pressure, heavy-load, and corrosive media. The wear, scratches, and scratches of various rollers of the machinery and equipment, coupled with corrosion, high-temperature oxidation and other damages start from the surface and gradually cause The failure of parts is the main factor restricting paper products. In the paper industry, the entire process from pulp production to finished paper forming, the main parts using thermal spray coating are: calender rolls, drying cylinders, wear plates for wood conveying discs, fan impellers, conveying screws, cooking pots, black Liquid boiler pipes, jaw jaws, paper dewatering plates, pump shafts and bushings, mechanical seal rings, etc. According to the specific use environment, various coatings can be used for corrosion protection and special functional surfaces, so as to prolong the service life of the workpiece and reduce the cost.

At present, thermal spraying technology is widely used in the maintenance of papermaking equipment. After atomization, the material is sprayed to the workpiece to form a thermal spraying method of a coating with high bonding strength, low porosity and low surface roughness. This spraying method has many significant advantages: 1. High bonding strength of the coating; 2. , It can effectively improve the wear resistance, high temperature resistance and corrosion resistance of the workpiece; 3. Extend the service life of the equipment and improve the production efficiency.

Thermal spray wear-resistant coatings can be applied to papermaking equipment such as dewatering box panels, coating blades, papermaking dryers, calender rolls, and high-speed rewinders.

Hot information