The boiler includes five systems: combustion system, material circulation system, coal preparation system, wind and smoke system, and slag and ash removal system. Today, let's first introduce the furnace combustion system, material circulation system, and coal-fired preparation system.

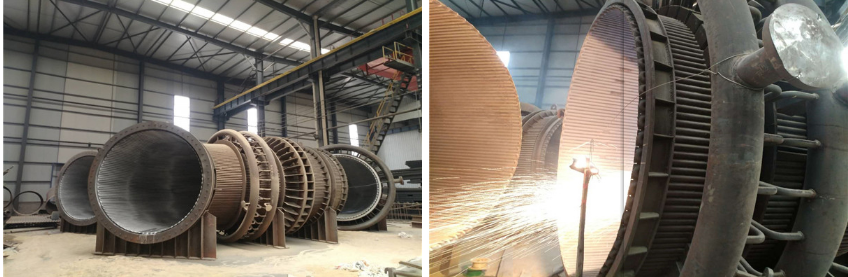

The heart of the circulating fluidized bed boiler is the furnace, from which the fuel and limestone for desulfurization are fed.

The cyclone separator captures the solid particles leaving the furnace, distributes the flow of solid particles through the water-cooled conical valve, and a part is directly sent to the lower furnace through the return feeder to maintain the balance of solid particles in the main circulation loop; the other part is separated from the cyclone separator The solid particles that come down are fed into the furnace after releasing heat through an external heat exchanger arranged in a similar bubbling bed. After separation, clean flue gas containing a small amount of fly ash enters the tail shaft, passes through the air preheater and the fly ash collection system, and is discharged into the atmosphere from the chimney.

Boiler soda system: The high pressure system includes economizer, drum, evaporative heating surface and superheater. The boiler feed water is first led to the inlet header of the economizer arranged in the tail flue, and flows upward through the horizontally arranged economizer tube group and then enters the boiler drum through the economizer outlet pipe. When there is no feed water flowing into the drum during the start-up phase, the economizer recirculation pipeline can lead the boiler water from the drum to the economizer inlet header to prevent the water in the economizer tube from stagnant vaporization.

Hot information