Thermal spraying is a surface strengthening technology and an important part of surface engineering technology. It has always been a new technology project promoted by my country. With the development of science and technology, thermal spraying technology has been widely used in China Research and development are getting more and more attention. The development trends and characteristics in recent years are:

1. Use thermal spraying technology to repair and strengthen the localization of large-scale key equipment and imported parts. There have been many successful application examples in this regard in recent years.

2. Due to the wide temperature range of the heat source, the coating materials that can be sprayed include almost all solid-state engineering materials, such as metals, ceramics, cermets, plastics and their composites, etc. Surfaces with various functions (such as wear resistance, corrosion resistance, high temperature resistance, oxidation resistance, insulation, thermal insulation, biocompatibility, infrared absorption, etc.).

3. During the thermal spraying process, the degree of heating on the surface of the substrate is small and controllable.

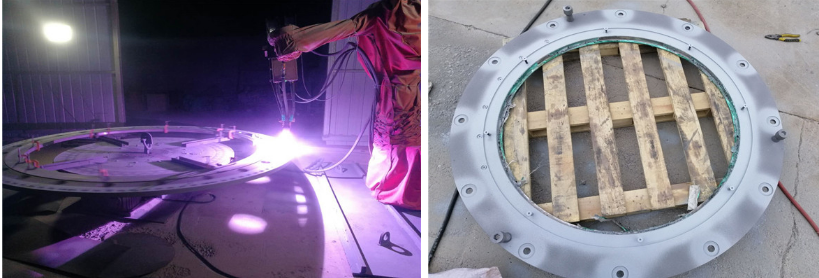

4. The equipment is simple and the operation is flexible. It can spray a large area of large components, and can also spray on a designated part. It can be sprayed indoors in the factory, or it can be constructed on the outdoor site.

5. There are fewer procedures for spraying operation, and the construction time is shorter, which is more economical.

Hot information