The metallurgical industry is a high-temperature smelting and processing industry of metals. Most of its main production equipment operates under harsh conditions such as high temperature, high load, fatigue, wear, and corrosion. An important trend in the development of contemporary metallurgical industry equipment is to use various composite materials and surface strengthening technologies, especially thermal spraying technology, to prepare coatings with high temperature resistance, thermal shock resistance, wear resistance, corrosion resistance and special functions. Achieve comprehensive benefits such as improving functions, saving energy, saving materials, extending the service life of key components and vulnerable components, and reducing costs.

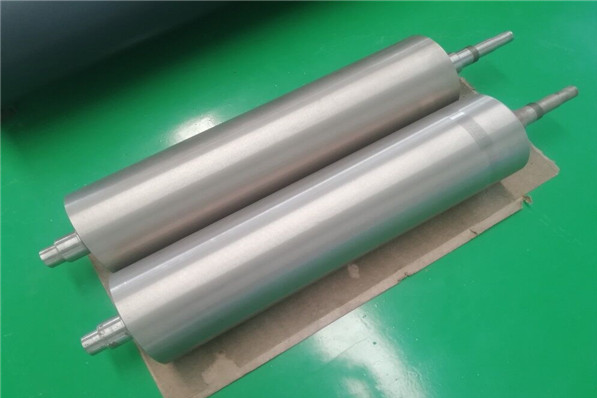

In the past two decades, thermal spraying technology has been more and more widely used in the metallurgical industry, and has achieved great results. Thermal spraying is used in all important aspects of steel production, especially in various high-temperature furnace rollers, guide rollers, feed rollers and other roller and shaft products.

The application of thermal spraying technology in continuous annealing furnace rolls is remarkable. In the production process of cold-rolled steel plates and thin plates, continuous annealing furnaces anneal the cold machine plates. The reducing gas is introduced into the annealing furnace, and the temperature in the furnace is as high as 900 ℃ or more. The annealing furnace is generally composed of a heating zone, a heat preservation zone and a cooling zone, and is divided into a vertical or horizontal structure. A continuous annealing furnace has a large number of furnace rollers in contact and friction with the surface of the copper plate at high temperature. The main technical requirements for annealing furnace rolls through thermal spray repair are as follows:

①High temperature oxidation resistance, can withstand high temperature of about 1000 degrees.

② Friction and wear of high temperature resistant steel belt The moving speed of the high temperature steel belt on the surface of the furnace roll is 50m/s or even higher.

③ Resist high temperature accumulation or nodules.

④It has a certain friction coefficient to facilitate the transmission of the steel belt, so that it will not "slip".

⑤ Thermal shock resistance The coating sprayed on the surface of the annealing furnace roller has better thermal shock resistance and no peeling in the thermal cycle from high temperature to room temperature.

Generally speaking, for metallurgical products used at room temperature and medium temperature, thermal spraying processes such as flame spraying remelting, plasma spraying, and plasma spraying welding are used to prepare self-fluxing alloy welding layers with wear resistance, corrosion resistance and heat resistance.

Hot information