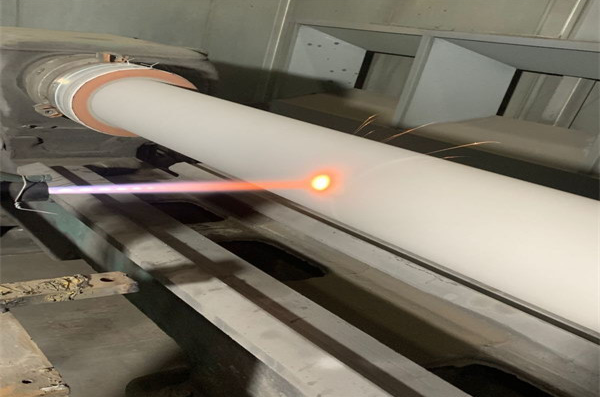

Thermal spraying technology is a method of using a heat source to heat the sprayed material to a molten or semi-molten state, and spraying and depositing it on the pretreated substrate surface at a certain speed to form a coating. Thermal spraying technology is to create a special working surface on the surface of ordinary materials, so that it can achieve: anti-corrosion, wear-resistant, anti-friction, high temperature resistance, anti-oxidation, heat insulation, insulation, electrical conductivity, microwave radiation resistance, etc. This function makes it achieve the purpose of saving materials and energy. We call the special working surface coating, and the working method of making coating is called thermal spraying.

From the analysis of the principle and process of thermal spraying technology, thermal spraying technology has the following characteristics:

1. Because the temperature range of the heat source is very wide, the coating materials that can be sprayed include almost all solid engineering materials, such as metals, alloys, ceramics, cermets, plastics and their composites. Surfaces with various functions (such as wear resistance, corrosion resistance, high temperature resistance, oxidation resistance, insulation, thermal insulation, biocompatibility, infrared absorption, etc.).

2. The heating degree of the surface of the substrate during the spraying process is small and can be controlled, so it can be sprayed on various materials (such as metal, ceramics, glass, cloth, paper, plastic, etc.), and the organization and performance of the substrate There is almost no influence, and the deformation of the workpiece is also small.

3. The equipment is simple and the operation is flexible. It can not only spray large areas of large components, but also spray the designated parts; it can be sprayed indoors in the factory or constructed on the outdoor site.

4. There are fewer procedures for spraying operation, shorter construction time, high efficiency and more economical.

With the improvement of thermal spraying application requirements and the expansion of the field, especially the progress of spraying technology itself, such as the increasing energy and sophistication of spraying equipment, the gradual increase in the variety of coating materials, and the gradual improvement of performance, thermal spraying technology has achieved great success in the past ten years. The rapid development has been more and more widely used in various fields of the national economy.

Hot information