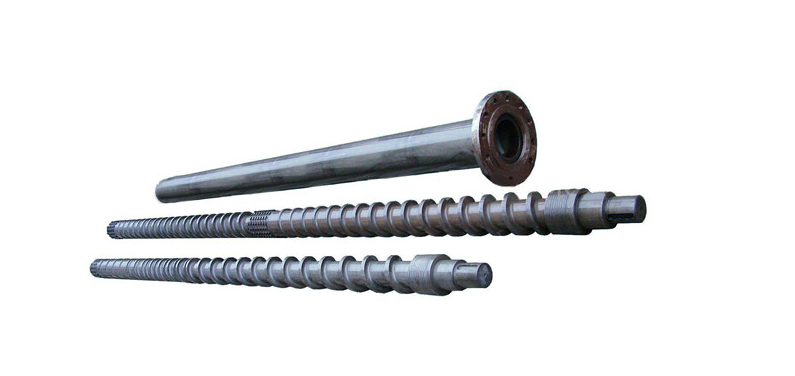

1. Thermal spraying technology applied to plastic extruder screw

Plastic extruder is the main equipment for plastic molding processing. It uses electric heating to heat and melt plastic powder or flakes, and then extrude them with an extruder screw. The extruder screw is the key part of the plastic extruder. It is subjected to a lot of torsion, and is subjected to abrasive wear and heating of plastic lumps and molten plastic. The working conditions are relatively harsh, especially the top of the extrusion screw is easy to Cracks, cracks or even peeling occurs.

The use of thermal spraying technology to strengthen the surface of the screw top of the screw of the plastic extruder is an effective technology. One method is to use flame spray welding technology to spray a nickel-based self-fluxing alloy welding layer with a thickness of about 1mm at the top of the spiral; the other method is to use supersonic flame spray technology to spray WC12% 1 (mass) Co Quality alloy coating. The coating formed by thermal spraying technology has high bonding strength with the substrate and strong compactness, which can increase the service life of the extruder screw by more than one time.

2. Other equipment applications such as: plastic shredder nozzles and plastic film production rolls.

2. Other equipment applications such as: plastic shredder nozzles and plastic film production rolls.

In the production of plastic films, such as the production of polyvinyl chloride plastic films, the surface of the roller for winding the film is required to be wear-resistant, smooth, with a low coefficient of friction, without scratching the film, and making the film not stick to the surface of the roller.

A layer of AL2O3 ceramic coating is sprayed on the surface of the winding roller by the plasma spraying process, which greatly improves the wear resistance, makes the film not stick to the roller surface, and ensures the quality of the plastic film.

Hot information