Brush plating is an electroplating method that relies on a pad or brush in contact with the anode to provide the electrolyte required for electroplating. During electroplating, the pad or brush moves on the cathode to be plated. Brush plating uses a specially developed series of brush plating solutions, various forms of pens and anodes, and dedicated DC power supplies. When working, the workpiece is connected to the negative pole of the power supply, the plating pen is connected to the positive pole of the power supply, and the surface of the workpiece is wiped by the wrapped anode immersed in the solution. And it gradually thickens with time. Because the workpiece and the coating pen have a certain relative movement speed, it is an intermittent crystallization process for each point on the coating.

Brush plating technology has its own unique characteristics in terms of technology, and its characteristics can be summarized as follows:

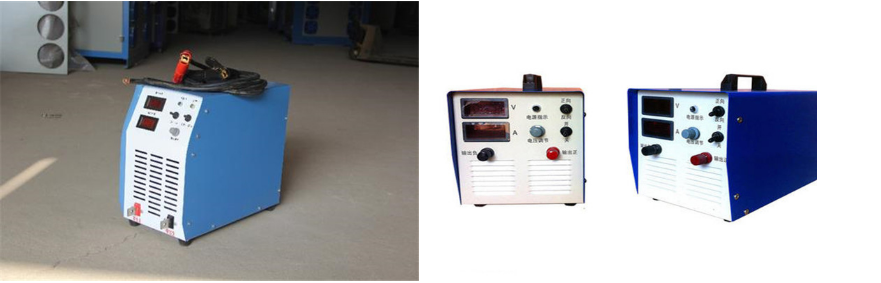

1. The equipment is simple, does not require a plating tank, is easy to carry, and is suitable for field and on-site repairs. Especially for the on-site non-disintegration repair of large and precision equipment, it has more practical value.

2. The process is simple, the operation is flexible, and the parts that do not need to be plated should not be protected with a lot of materials; the uniformity of the thickness of the coating can be controlled, and it can be plated evenly or unevenly.

3. The metal ion content in the plating solution is high, so the plating speed is fast.

Hot information