When it comes to the hardness of materials, most people seem to know that steel is harder than aluminum alloy. Among all types of steel, tool steel is harder than low carbon steel. The hardness of steel generally depends on the existence of Asada powder (also known as martensite) in its structure. If steel contains more martensite, it becomes harder. And the more martensite, the harder it is. Since most steel is called hard by martensite, martensite is called the "hard ancestor". If, in addition to Martensite, the structure of steel is added with chromium carbide particles, its hardness will be even higher. Many tool steels rely on the cooperation of chromium carbide and martensite to achieve high hardness.

However, despite the toughness of tool steel, compared with the use of tungsten carbide as the main component, the carbide alloy material made is still a big difference. Although the hardness of aluminum oxide and silicon carbide is comparable to that of tungsten carbide, their industrial applications are very limited. Although diamond is harder than tungsten carbide, it has no industrial use. In addition to hardness, tungsten carbide is also very beautiful and durable. As a result, tungsten carbide easily ascended to the throne of the "hard king".

general composition of tungsten carbide alloy materials

Although the main component of the early tungsten carbide alloy materials was tungsten carbide, cobalt was used as the binder (that is, the cobalt was used to bond the tungsten carbide grains together). However, if the percentage of tungsten carbide is reduced and replaced with titanium carbide or tantalum carbide, materials with different properties can also be made. The general composition of this material is shown in the following table: (weight percentage)

Tungsten carbide Cobalt Tantalum carbide Titanium carbide

97% 3%

94% 6%

87% 13%

51% 7% 10% 32%

82% 10% 8%

The above table lists the composition of some tungsten carbide alloy materials. The higher the amount of tungsten carbide and titanium carbide, the greater the hardness. However, Lexability is relatively reduced.

manufacturing method

(1) Preparation of tungsten carbide powder: using mineral processing technology to crush and separate tungsten-containing ore into a concentrate with high tungsten content. The tungsten-containing concentrate is mixed with aluminum carbide or calcium carbide and heated, and the high heat generated is mixed with aluminum carbide or calcium carbide and heated, and the high heat generated exceeds more than 2,100 degrees Celsius, so tungsten carbide is formed Up. After cooling, this tungsten carbide can be crushed to extremely fine powder. Another manufacturing method is to mix tungsten powder and carbon together to make tungsten carbide at high temperature.

(2) The production of alloy: tungsten carbide and cobalt are mixed in a certain proportion, pressed into various shapes, and then semi-sintered. This sintering process is usually carried out in a vacuum furnace. Place it in a vacuum furnace to complete sintering. The temperature at this time is about 1,300 to 1,500 degrees Celsius.

some properties of tungsten carbide alloy materials

The micro metal structure of the tungsten carbide alloy material is shown in Figure 3. This is an alloy containing 94% tungsten carbide and 6% cobalt. The particles are extremely fine, and the white lumps are larger tungsten carbide particles. Figure 4 shows the block structure under higher magnification. Between the tungsten carbide particles is a cobalt particle binder.

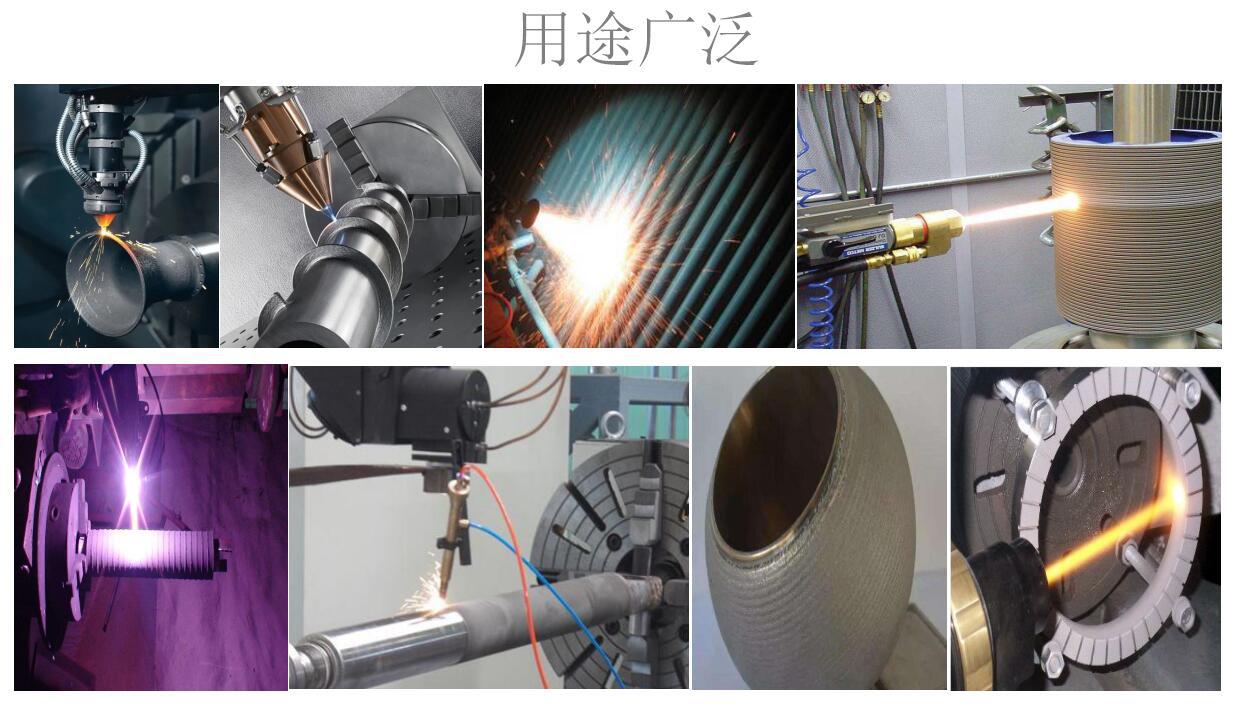

In terms of wear resistance, corrosion resistance, high temperature, and hardness, tungsten carbide alloy materials are about a hundred times stronger than the hardest steel. If any machine or mechanical device needs good wear-resistant materials, it is best to first consider using this tungsten carbide alloy material. Perhaps the cost of the product will be higher, but it is more durable, which can reduce the chance of mechanical failure or replacement.

Hot information