The particle size distribution of the metal powder can be analyzed by a laser particle size analyzer. The particle size range of powders commonly used in metal 3D printing is 15~53μm (fine powder) and 53~105μm (coarse powder). This particle size range is divided according to the metal printers with different energy sources. Printers with laser as the energy source have a fine focus spot and are easier to melt fine powder. It is suitable to use 15~53μm powder as consumables because it is within this particle size range. The powder has good fluidity and is easy to dissolve. The powder replenishment method is to spread the powder layer by layer; the printer with plasma beam as the energy source has a slightly coarse focus spot, which is more suitable for melting coarse powder, suitable for 53~105μm The powder is used as a consumable, and the powder supply method is coaxial powder feeding.

3. Reference indicators such as sphericity, loose density, fluidity, etc.

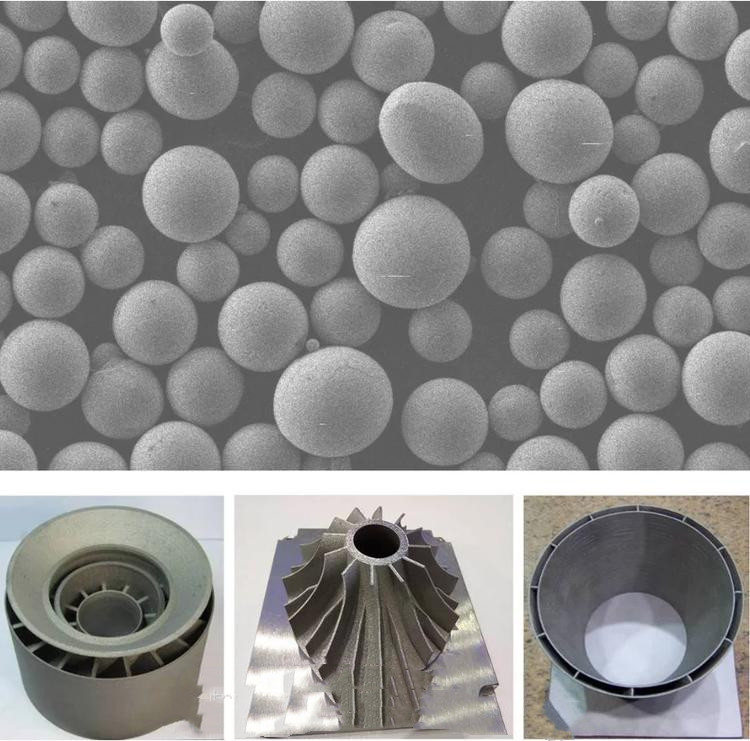

Sphericity is the degree to which the metal powder particles are close to the sphere, which is generally qualitatively analyzed by scanning electron microscope (SEM). The above picture shows the SEM morphology photos of different metal powders. It can be seen that the sphericity of the powder particles on the left is better than that of the powder on the right. Generally speaking, the sphericity is good, and the fluidity of the powder particles is also good. It is easier to spread and feed powder in metal 3D printing.

Fluidity refers to the time required for a certain amount of metal powder particles to flow through a measuring tool with a specified aperture. The usual unit is s/50g, which can be measured by a Hall flow meter. The smaller the value, the better the fluidity of the powder. Fluidity can also be characterized by the angle of repose. The angle of repose refers to the angle measured in a gravitational field when the gravity and the friction between the particles are balanced when the particles slide on the free slope of the metal powder accumulation layer. This is a simple method to test the fluidity of metal powder. The smaller the angle of repose, the smaller the friction and the better the fluidity, which is more conducive to powder spreading and powder feeding.

The bulk density is the mass of the metal powder in a certain volume, which can be measured by the funnel method. The loose packing density is only used as a reference index, which characterizes the degree of packing compactness of the powder during the replenishment process, and its influence on the density of the metal printed final product is uncertain.

Hot information