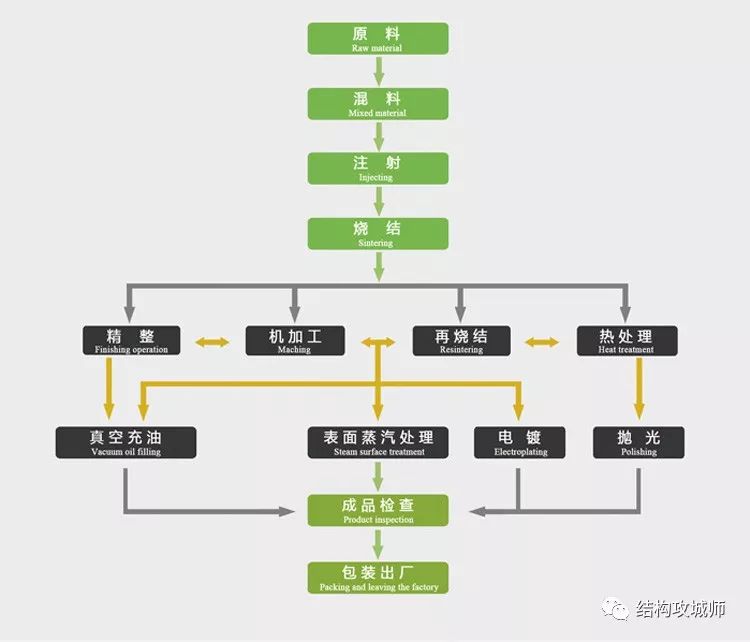

MIM process flow

The MIM process flow combines the flexibility of injection molding design with the high strength and integrity of precision metals to achieve a low-cost solution for extremely complex geometric components. The MIM process is divided into four unique processing steps (mixing, forming, debinding and sintering) to realize the production of parts, and determine whether surface treatment is required according to the product characteristics.

mixing

Fine metal powder with a particle size of less than 20µ is mixed with thermoplastics and paraffin binder in precise proportions. The volume of metal powder and binder is about 60:40. The mixing process is carried out in a special mixing equipment, heated to a certain temperature to melt the binder. In most cases, mechanical mixing is used until the metal powder particles are evenly coated with a binder and cooled to form particles (called raw materials), and these particles can be injected into the mold cavity.

Forming

The equipment and technology of injection molding are similar to those of injection molding. The granular raw material is fed into the machine to be heated and injected into the mold cavity under high pressure to form a green part (green part) after cooling and demolding only at about 200°C to melt the binder (fully fused with the metal powder). The whole process can be carried out. The mold can be designed with multiple cavities to improve productivity. The cavity size is designed to be 20% larger than the metal parts to compensate for the shrinkage produced during the sintering process. The shrinkage change of each material is accurate and known.

Degreasing

Degreasing is the process of removing the binder from the formed part. This process is usually done in several steps. Most of the binder is removed before sintering, and the remaining part can support the parts into the sintering furnace. Degreasing can be accomplished by a variety of methods, the most commonly used is solvent extraction. The degreased parts are semi-permeable, and the remaining binder is easily volatilized during sintering.

sintering

The degreased parts are placed in a furnace controlled by high temperature and high pressure. The part is slowly heated under the protection of gas to remove residual adhesive. After the binder is completely removed, the part is heated to a very high temperature, and the voids between the particles disappear due to the fusion of the particles. The part directional shrinks to its design dimensions and transforms into a dense solid. For most materials, the typical sintered density is theoretically greater than 97%. The high sintering density makes the product performance similar to forged materials.

Surface treatment

According to specific requirements, some parts may require surface treatment after sintering. Heat treatment can improve the physical properties of metals. Electroplating and painting can be applied to high-density materials. Provide welding or cooling processing technology.

Hot information