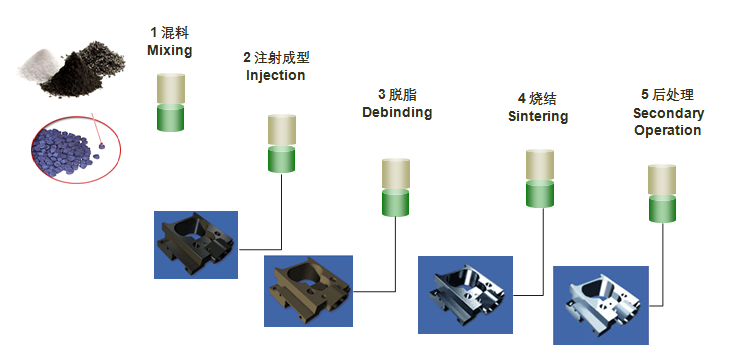

current position:Information and data>MIM process flow

1. Mixing

The mixing process is carried out in a special mixing equipment, heated to a certain temperature to melt the binder. In most cases, mechanical mixing is used until the metal powder particles are evenly coated with the binder, and then they are extruded into the machine into strips and cut into pellets (called feed). These raw material particles can be directly put into the injection Injection molding is carried out in the machine.

2. Injection

The equipment and technology of injection molding are similar to those of injection molding. The granular material is fed into the machine to be heated and injected into the mold cavity under high pressure. Only when designing the cavity size, the shrinkage rate of the product during the sintering process should be taken into consideration. Usually, the shrinkage rate is known and accurate. In addition, controlling the injection temperature, mold temperature, injection pressure, holding time and other molding parameters is very important to obtain stable green body quality.

3. Degreasing

Debinding is the process of removing the binder from the molded part. This process is usually completed in several steps. Most of the binder is removed before sintering, and the remaining part can support the part to enter the sintering furnace.

4. Sintering

The degreased parts are placed in a furnace controlled by high temperature and high pressure. The part is slowly heated under the protection of gas to remove residual adhesive. After the binder is completely removed, the part is heated to a very high temperature, and the voids between the particles disappear due to the fusion of the particles.

5. Post-processing

According to specific requirements, some parts may require surface treatment after sintering. Such as heat treatment, electroplating, PVD, spraying, CNC, etc.

Hot information