The one-step synthesis of cemented carbide is based on the discharge plasma ball milling technology. First, the original W, C, and Co powders are prepared by plasma ball milling to prepare nanocrystalline WC-Co composite powder. The ball milling time is about 1-3h, and then the prepared above The composite powder is formed into a green compact by cold pressing, and finally a WC-Co cemented carbide block is synthesized by one-step carbonization sintering in a vacuum or low-pressure sintering furnace, as shown in Figure 2. The cemented carbide prepared by this method is usually a high-performance nanocrystalline or ultrafine WC-8Co alloy.

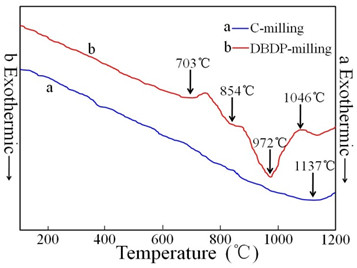

The picture shows the DSC curve of the WC mixed powder of ordinary ball milling for 3h and plasma ball milling for 3h. After plasma ball milling, the WC mixed powder will produce WC at about 900℃ (the new plasma ball mill can achieve WC synthesis below 800℃), which is compared with conventional carbon heat The carbonization temperature of the method drops by 300-500℃, which is tens to hundreds of hours shorter than the commonly used ball milling time in industry.

Hot information