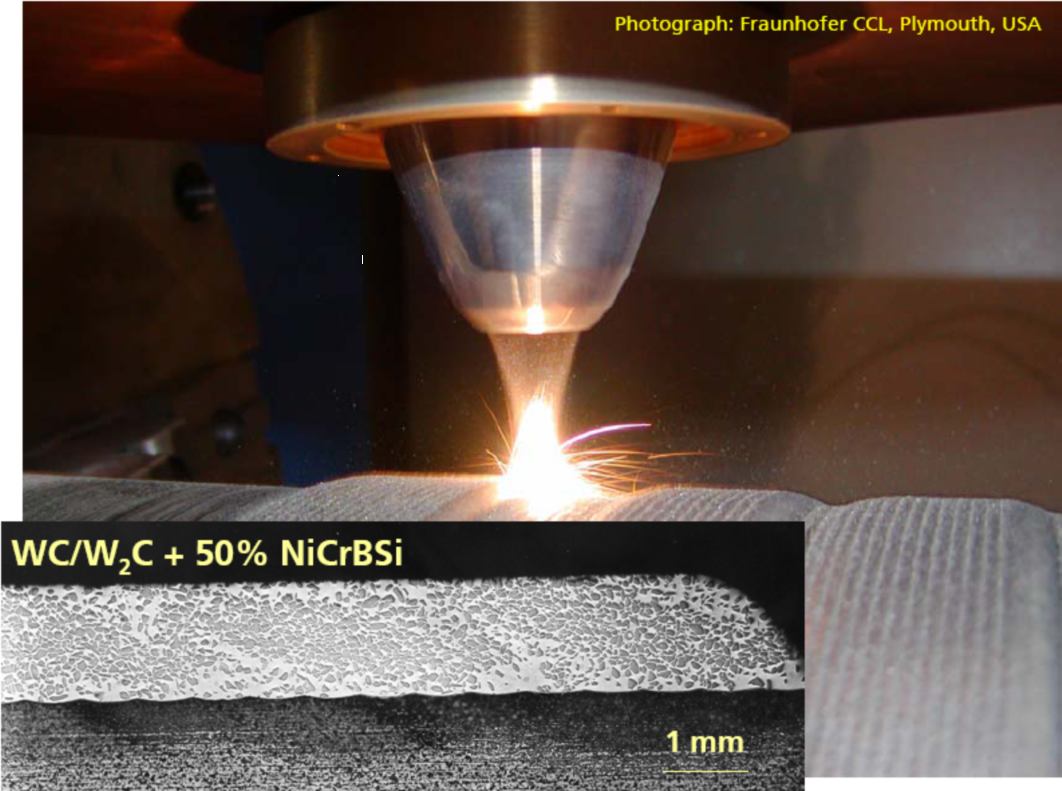

Laser cladding technology is an important branch of laser processing technology, also known as laser surface remanufacturing, laser surface additive manufacturing, etc. It is a new surface modification technology. The principle is to add a cladding material on the surface of the substrate and use a high-energy density laser beam to fuse it together with the thin layer of the substrate surface to form an additive cladding layer on the surface of the substrate that is metallurgically combined.

From the principle of laser cladding, it is not difficult to see that "adding cladding material on the surface of the substrate" is the prerequisite for laser cladding, and we usually call the process of "adding cladding material on the surface of the substrate" as "Feeding powder".

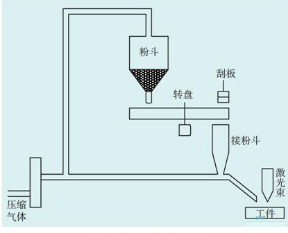

The powder feeding method of laser cladding is mainly divided into two types: preset powder feeding and synchronous powder feeding. The preset powder feeding refers to placing the laser cladding powder on the path of the laser spot in advance. As the spot moves, The preset powder is melted and solidified together with the base material to obtain a laser cladding layer. There are two ways to realize the preset powder feeding, one is to spread powder manually, and the other is to use a gravity powder feeder to feed the powder, and the powder is preset on the path of the light spot.

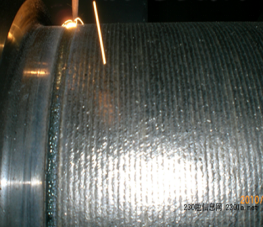

Schematic diagram of scraper gravity preset powder feeding/Gravity preset powder feeding laser cladding layer state

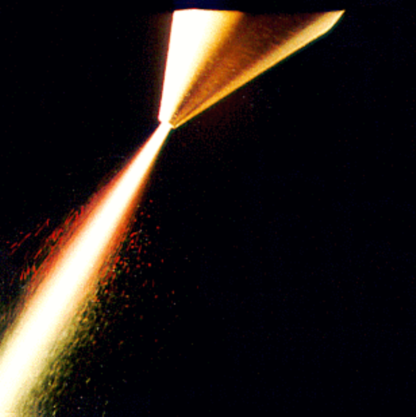

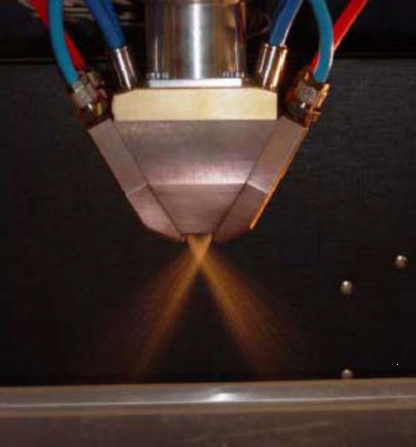

Synchronous powder feeding is to use an air-carried powder feeder to directly transport the laser cladding powder into the light spot. As the light spot moves on the surface of the workpiece, a cladding layer is formed. There are two ways to realize synchronous powder feeding, one is lateral powder feeding and the other is coaxial powder feeding. Compared with the preset powder feeding method, the synchronous powder feeding can achieve good air protection, so that the performance of the cladding powder itself is not affected by elements such as oxygen and nitrogen in the air, and the perfect performance of the cladding layer is realized.

Synchronous circular coaxial powder feeding/Three way coaxial powder feeding/Lateral send powder

Side feeding nozzles for synchronous feeding/Synchronous powder feeding distance light spot powder feeding nozzle

In addition to the above two powder feeding cladding methods, there is also a cladding method for laser cladding, which is wire feeding cladding, that is, through the wire feeding mechanism, the special metal wire is directly fed into the light spot, and the substrate is melted and solidified together to achieve Laser cladding layer. Compared with powder feeding cladding, wire feeding cladding can achieve no waste of cladding materials, with a utilization rate of 100%, which is much higher than powder feeding cladding (the average utilization rate of powder feeding cladding is about 75%). The disadvantage is The heat-affected zone is too large, good gas protection cannot be achieved, there are many cladding defects, and the adjustment of process parameters is difficult.

Hot information