current position:Information and data>Characteristics of tungsten carbide spray coating

Characteristics of coating preparation:

1. The flame velocity is very high, generally 5 times the speed of sound.

2. The speed of spraying powder is also very high, up to 2000 m/s.

3. The coating is highly dense, the bonding strength is high, the porosity can be less than 1%, and the bonding strength can be greater than 70Mpa.

4. The coating material has a low degree of oxidation. Less carbon loss and high coating hardness.

5. The powder particles have obtained great kinetic energy in the high-speed flame flow, and the impact effect on the substrate and the deposited particles is significant. Beijing Qinhe Technology Co., Ltd. And only a small part of the deposited particles have liquid/solid phase solidification and shrinkage processes , Most of them are solid phase

Deformation, compressive stress is generated in the coating which is helpful to improve the reliability of the coating.

6. Some specific materials can meet repair occasions, Beijing Qinhe Technology.

7. High-speed impact and strong deformation cause distortion of the material's crystal lattice, increase the activity of the material, and thus increase

It is possible to form a physical bond with adjacent particles or matrix materials, and the reliability of the coating is extremely high.

8. The workpiece is not deformed.

Operating procedures:

Customers provide parts, we carry out spray processing, customer acceptance after completion.

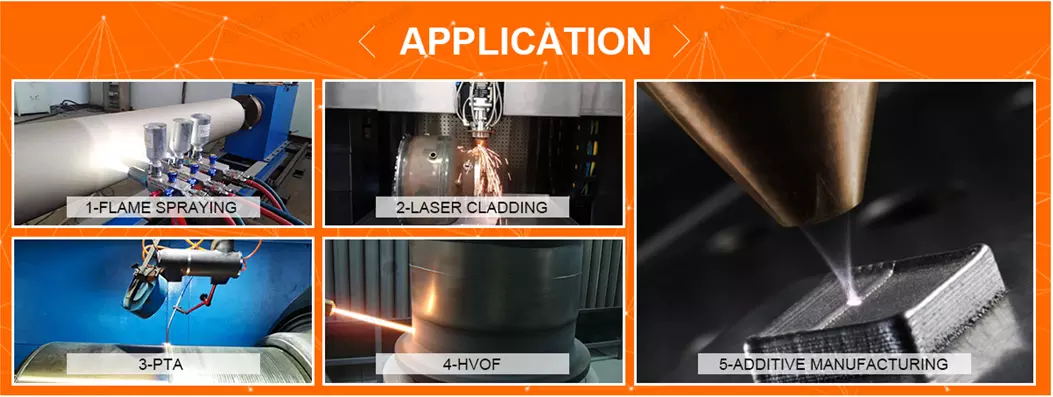

Application areas,

Mainly engaged in ceramic coatings, currently providing protective coatings, personalized protection scheme design, engineering technology for electric power, steel, cement and other enterprises

A comprehensive protection solution integrating technical services. Serving customers involving aerospace, petrochemical, papermaking, printing, packaging, electronics, transportation

And many other fields. The scope of services includes various shafts, pump valves, sealing rings, sputtering targets, corrugated rolls, various valves, rolls, fan impellers,

Thermal spraying of various coatings such as wear-resisting, high-temperature resistance, corrosion resistance, conductivity, insulation, etc. of parts and components of high wear-resistant products such as drawing tower wheels.

Wear resistance, anti-corrosion, heat insulation, papermaking; railway, machinery, automobile, steel, petroleum, chemical, printing, aerospace, electric power coal.

Plasma spraying thermal barrier coating and electrical insulation coating: such as ZrO2, Al2O3 coating, etc.

Plasma sprayed metal oxide wear-resistant coating: such as Cr2O3, Al2O3/Ti coating, etc., used for pump plungers, seal rings, shaft sleeves, godet rollers, etc.

Supersonic spraying wear-resistant and corrosion-resistant coatings: such as WC-Co, WC-Co-Cr, NiCr-Cr3C2, carbide, tungsten carbide spraying, wc spraying, etc., used for steam

Turbine blades, fan impellers, valve bodies, valve seats, etc.

Hot information