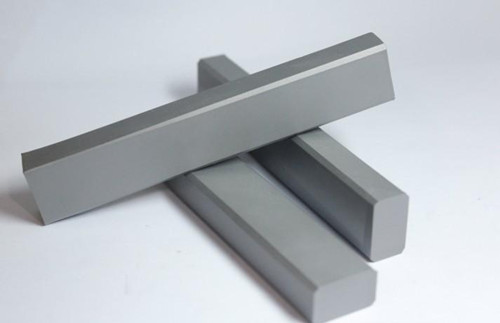

Cemented carbide sheet is also known as cemented carbide plate, cemented carbide sheet. It is one of the many materials of cemented carbide, named after its rectangular plate (or square). Cemented carbide plates are mainly made of metal WC tungsten carbide powder and Co cobalt mixed by metallurgical methods through powder milling, ball milling, pressing, and low-pressure sintering. The product body has good compactness, no holes, no blisters, and high dimensional precision (control blank tolerance Within ±2.2~±2.2, the precision blank is controlled within ±0.01), with less machining allowance, which can effectively improve your production efficiency and greatly reduce processing costs.

Cemented carbide sheet is also known as cemented carbide plate, cemented carbide sheet. It is one of the many materials of cemented carbide, named after its rectangular plate (or square). The main alloy components of cemented carbide plates are WC and Co. The content of WC and Co in cemented carbide plates for different purposes is not consistent, and the application range is extremely wide.

Cemented carbide sheet introduction

Cemented carbide sheet is one of the many materials of tungsten steel. It is made by powdering, ball milling, pressing and sintering by the metallurgy method. The content of WC and Co in the tungsten steel sheet for different purposes is not consistent. It has a very wide range, with excellent hardness, high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation resistance), low impact toughness, low expansion coefficient , Thermal conductivity and electrical conductivity are similar to iron and its alloys. It is also an excellent material for making high-temperature parts, wear-resistant parts, anti-shielding parts, and corrosion-resistant parts. The tungsten steel sheet of suitable material should be selected according to the specific application.

Cemented carbide sheet has excellent hardness, high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation resistance), low impact toughness, and low expansion coefficient , Heat conduction, electrical conductivity and similar characteristics of iron and its alloys, due to the great superiority of tungsten steel turning tools, they quickly spread in the industry. In just 50 years, due to the use of tungsten steel turning tools, the metal cutting speed has increased two hundred times, from ten meters per minute to more than two kilometers. The heat-resistant tungsten steel still maintains good elasticity and mechanical strength, and is generally used for thicker cutting, intermittent cutting and poor parts clamping. After coating, the effect is better, and it can be processed to various materials of HRC50°. Corresponding to general tungsten steel, it has 1 to 2 times the service life and excellent impact resistance.

Hot information